36

| WORLD FERTILIZER |

NOVEMBER 2016

necessary to produce this fertilizer in a UFT fluid bed

granulation plant.

Why sulfur-enhanced urea?

Sulfur is a plant macronutrient and it plays an important

role in crop development. In recent years, the importance

of sulfur has become a significant topic in the global

agricultural community, due to the rising incidence of soil

sulfur deficiency. Over the past several decades,

increasingly stringent fuel desulfurisation policies have

been implemented around the world in order to reduce

air pollution. These policies have been extremely

successful, but have simultaneously resulted in less

atmospheric sulfur deposition into agricultural soils.

Because sulfur is a vital crop nutrient, this reduced

deposition has meant that, today, many farmers must

provide additional sulfur to their crops in order to

achieve optimal yields.

The fertilizer industry has responded to the growing

sulfur deficiency with the introduction of various sulfur

containing fertilizers. However, these innovations have not

been enough to eliminate the deficit; and the sulfur gap

continues to grow. In 2015, The Sulfur Institute estimated

that approximately 10 million t more of sulfur were taken

out of soils than were replaced.

As the most widely used fertilizer globally, both

geographically and by volume, urea is seen as an ideal

sulfur delivery vehicle to help respond to the global soil

sulfur deficiency.

What is Urea-ES technology?

Urea-ES technology enables fertilizer producers to

incorporate micron-sized particles of elemental sulfur into

urea, as a convenient and cost-effective way of providing

plants with the sulfur nutrition they need.

Elemental sulfur is the most concentrated form of

sulfur and, as it is readily available, sulfur is an economical

source of plant nutrient sulfur. However, since plants take

up sulfur nutrient in the form of the sulphate ion,

elemental sulfur must also be oxidised by bacteria in the

soil before it is available to the plant.

To accelerate this oxidation process, Shell has

developed a process that micronises the elemental sulfur

into fine particles of, on average, less than 25

µ

m,

significantly increasing the surface area accessible to soil

bacteria (Figure 2). This way, the elemental sulfur can be

oxidised across the entire crop growth cycle, helping to

offer a season-long supply of sulfur nutrition.

While the Shell technology safely and efficiently

combines urea and sulfur into a stable emulsion, the

emulsion must then be granulated in order to be applied

to soils. In early 2015, Shell and UFT joined forces to

develop an end-to-end Urea-ES fluid bed granulation

process for producing granular sulfur-enhanced urea.

The value of sulfur-enhanced urea

Urea-ES technology has the potential to create meaningful

value for the fertilizer producer, through the distribution

chain and finally at the farm level.

At the fertilizer manufacturing facility, replacing a

portion of higher-cost urea liquor with lower-cost sulfur

can reduce overall input costs to the manufacturer. In

addition, in markets that recognise the importance of

sulfur as a plant nutrient, fertilizer producers may be able

to sell sulfur-enhanced urea at a premium price over

regular urea. Premium pricing for sulfur-containing

products is well documented in markets such as North and

South America, and Europe, for example.

Incorporating elemental sulfur into urea can produce

highly nutrient-dense formulations, since elemental sulfur

contains >99% nutrient. Compared to plain urea, which

contains 46% nutrient (46-0-0), Urea-ES with a formulation

of 40-0-0-13S contains 53% nutrient. Urea-ES with a

formulation of 35-0-0-24S has an even higher nutrient

density of 59%. For this reason, Urea-ES products have the

potential to save transportation and handling costs

throughout the distribution chain.

At the farm level, sulfur-enhanced fertilizers have the

potential to increase crop yield and improve crop quality

by offering plants a more balanced nutrition. Agronomic

trials performed since 2014 have shown equivalent

and/or improved performance over existing nitrogen and

sulfur fertilization programmes. In

addition, the product offers farmers a

convenient, all-in-one source of

nitrogen and sulfur, which does not

require blending.

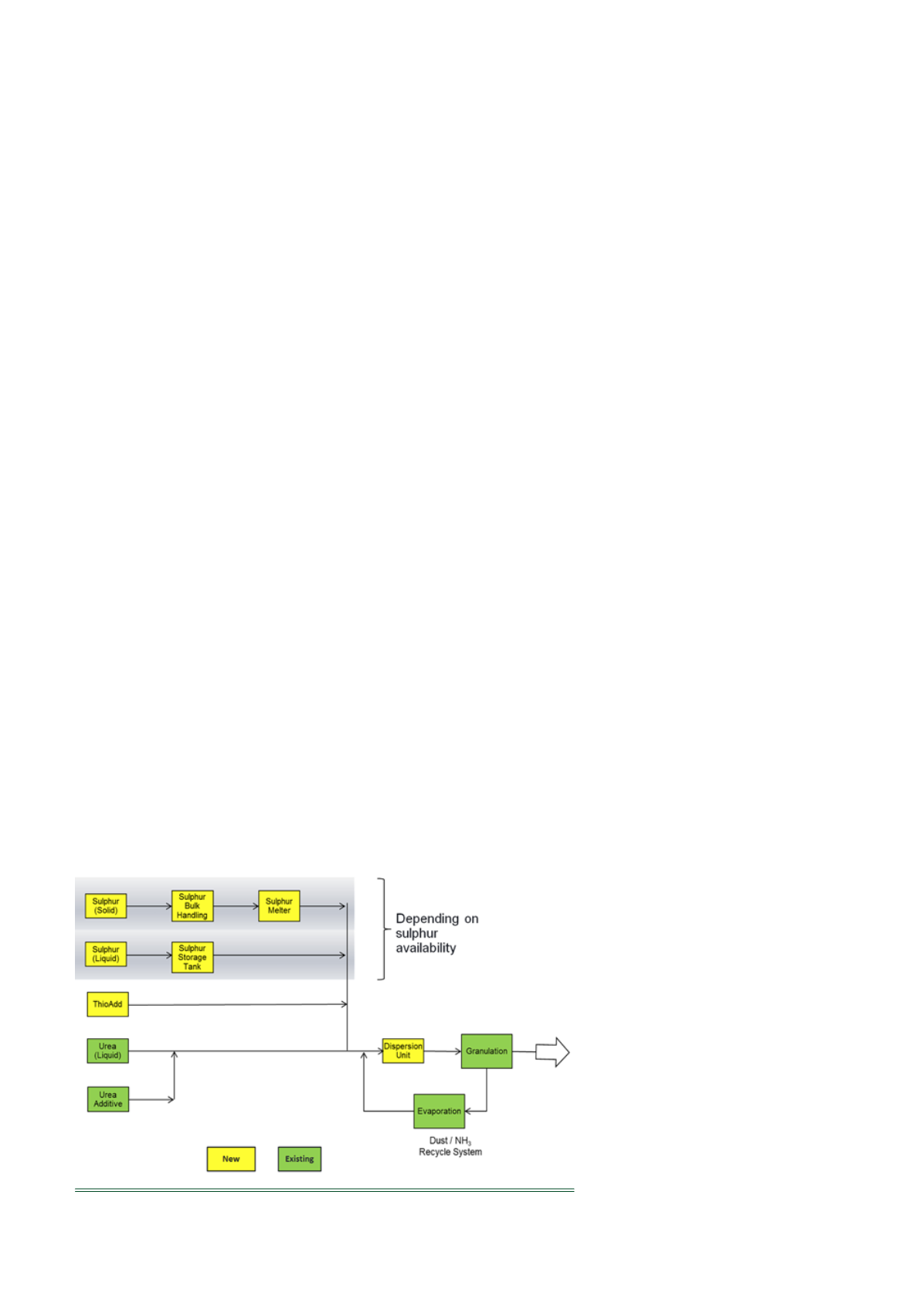

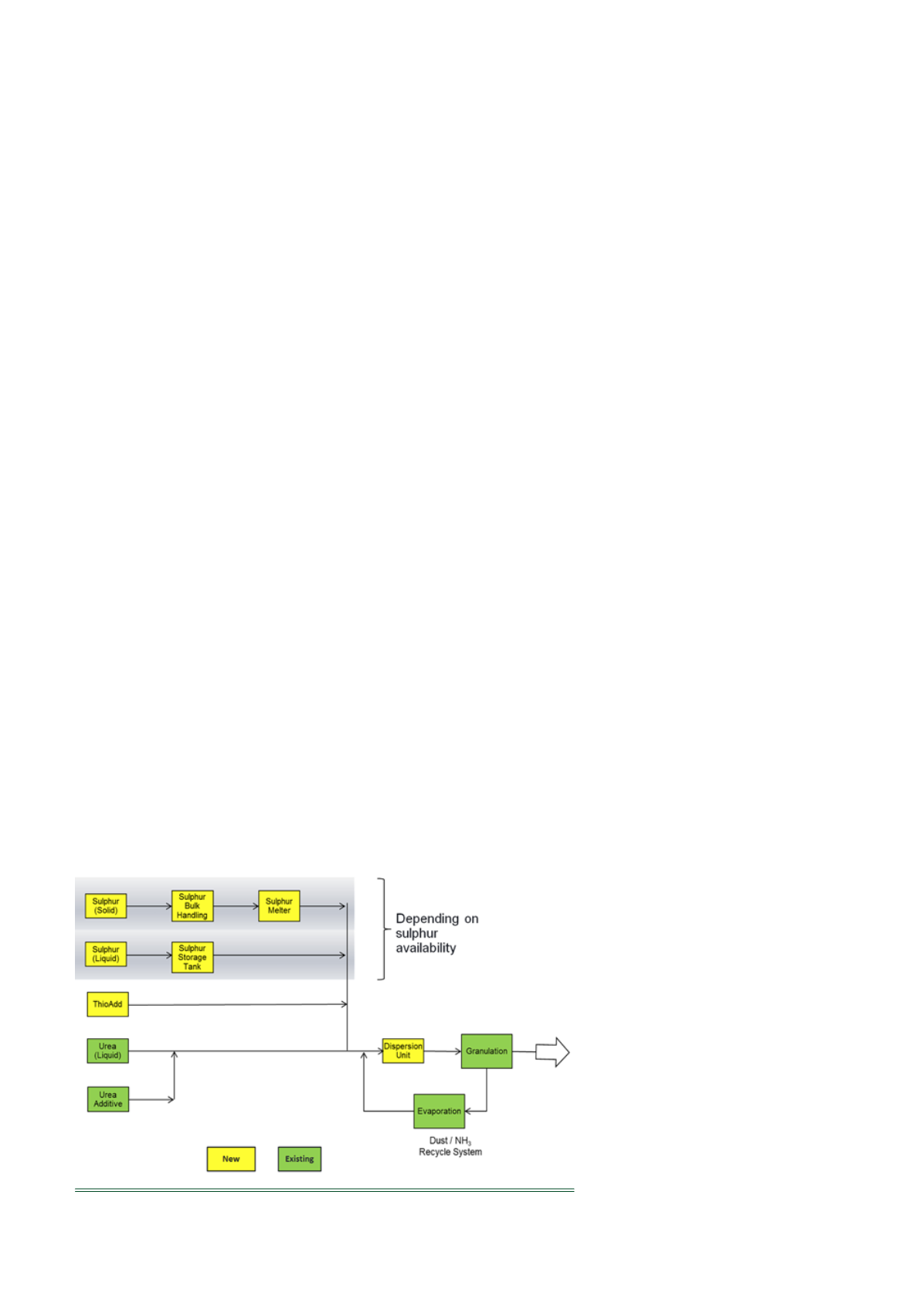

Simplified Urea-ES process

description

The production of Urea-ES takes place

across several steps, and involves the

combination of molten sulfur,

concentrated urea solution, and a

proprietary additive called ThioAdd.

ThioAdd is required to produce a

stable mixture of molten urea and

molten sulfur. Without it, due to the

significant differences in density and

surface tension between the two

liquids, a stable mixture cannot be

achieved, and the result is a visible

Figure 1.

Basic flowsheet for a sulfur-enhanced urea granulation plant.