40

| WORLD FERTILIZER |

NOVEMBER 2016

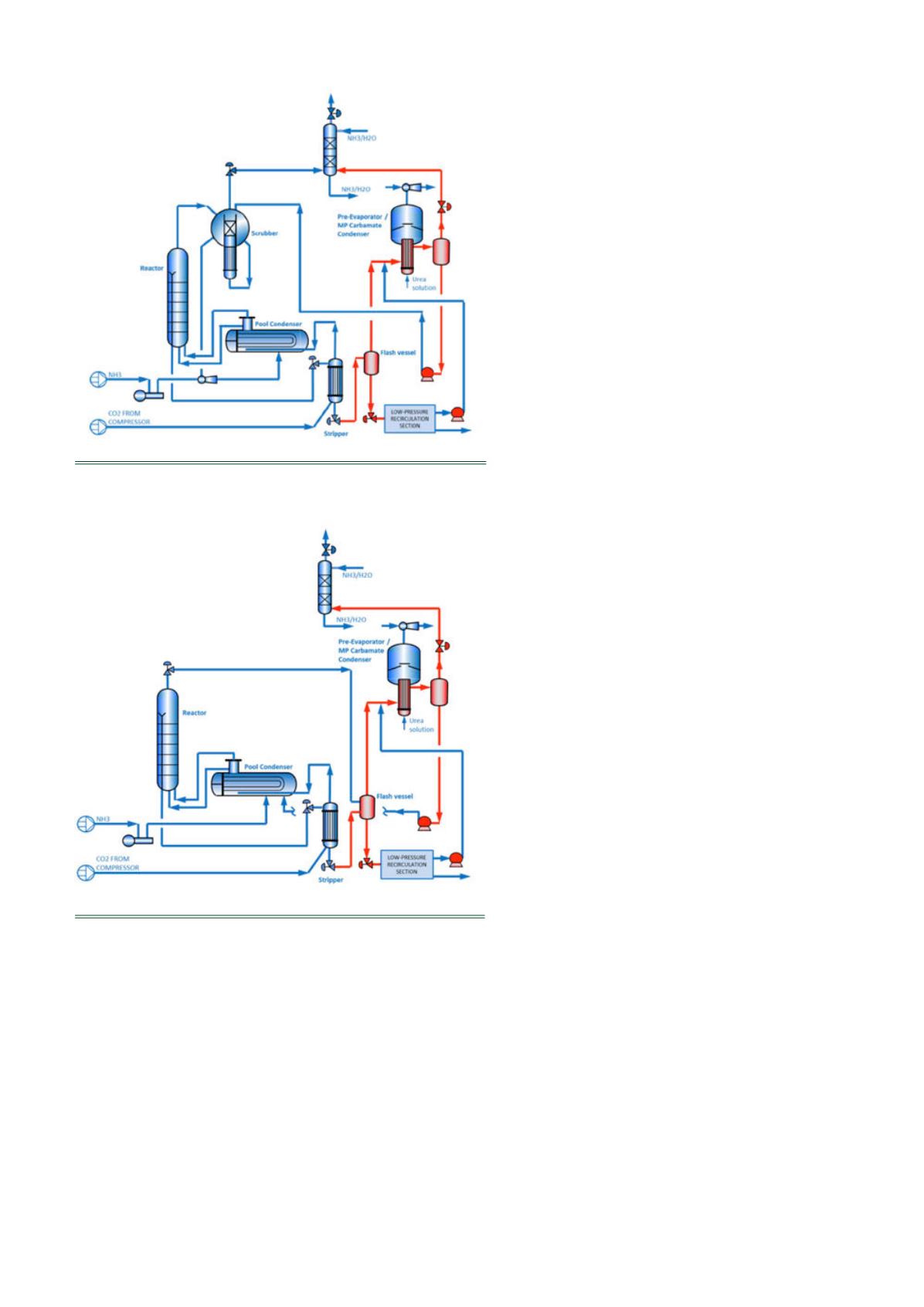

stripper are fed, along with the fresh carbon dioxide, to

the HP pool condenser, in which the released

condensation heat is used to produce low-pressure steam

that is used in downstream processing. Thus, to keep the

downstream section limited (a small LP section and no

MP section), HP steam is indirectly converted into LP

steam to achieve a high synthesis conversion. From the

point of view of investment cost alone, the only way to

go is to make the synthesis conversion rate as high as

possible. But when energy efficiency is given greater

importance, there is room for improvement in the urea

process.

Design concept

Stamicarbon’s concept typically reduces the steam

consumption by approximately 100 kg/t of final

product, through the installation of a small in-line

flashing step between the synthesis loop and the

traditional low-pressure stage (Figure 1).

As stated, the urea solution from the HP stripper

is flashed adiabatically at a pressure of about 2 MPa

in the flash separator. The urea solution leaving the

adiabatic flash separator is fed to the rectifying

column in the traditional 400 kPa low-pressure

section. The vapors from the adiabatic flash

separator are fed to the shell side of the

pre-evaporator. The heat of condensation released

in the shell side of the pre-evaporator is used to

concentrate the urea solution in the tube side of

this pre-evaporator. The resulting medium-pressure

carbamate is transferred into the synthesis loop by a

HP carbamate pump. The remaining vapors from the

medium-pressure stage are washed in a 400 kPa

absorber before being released into the atmosphere.

Omitting the HP scrubber

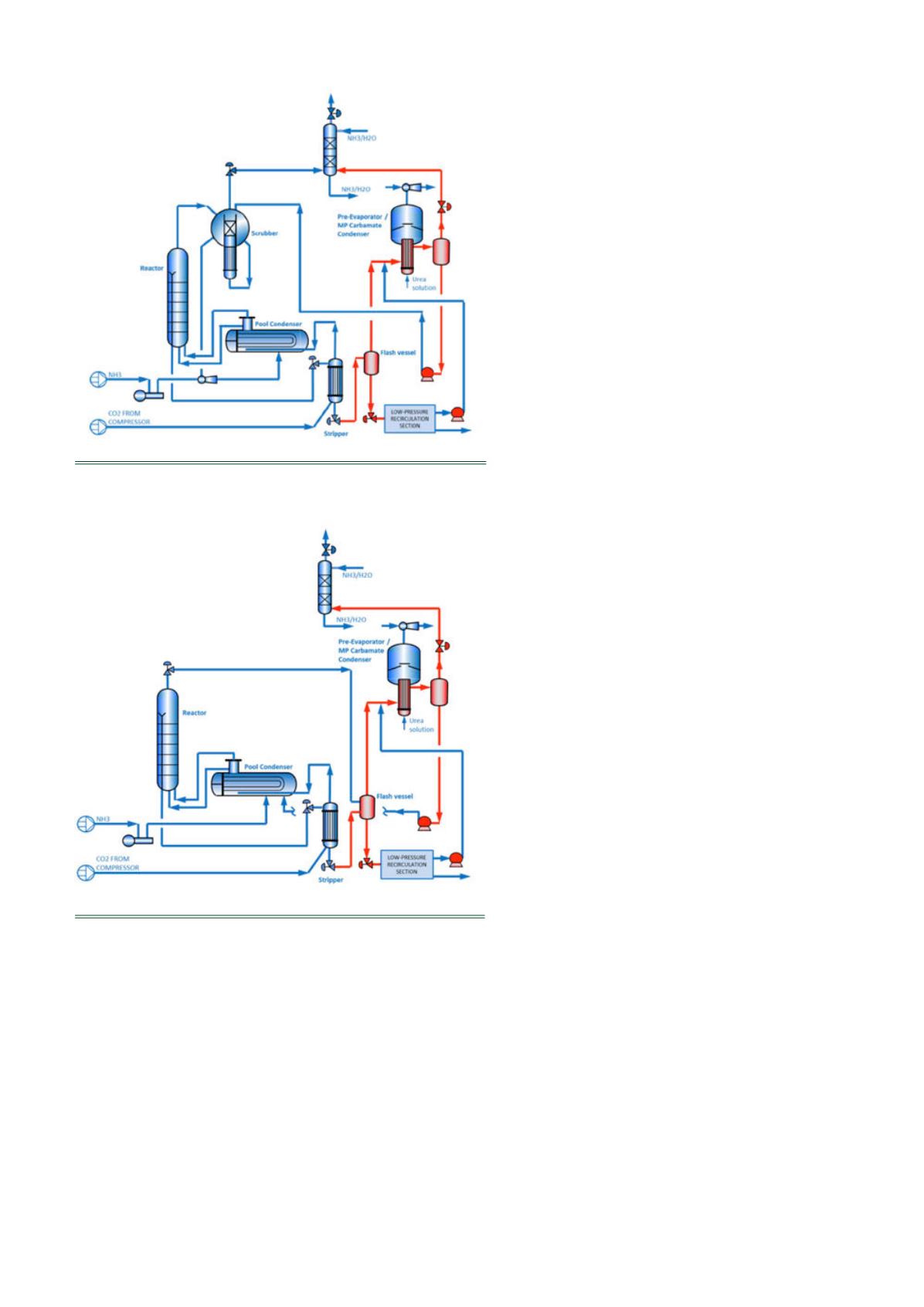

The concept can be realised without a HP scrubber in

the synthesis loop. This significantly reduces the

number of required high-pressure equipment items

(Figure 2).

In this configuration, the function of the HP

scrubber, which is to condense ammonia and carbon

dioxide (in the form of ammonium carbamate) out of

the vapors from the HP urea reactor, is taken over by

the pre-evaporator/MP carbamate condenser. This

design has an even better heat integration and

reduces the investment cost of the HP equipment, as

the HP scrubber, the CW circulation pump and the HP

ejector can all be dispensed with.

Investment and operating costs

Operating cost is one of the main factors determining

the cost price of the urea end-product, and its

biggest component is the cost of the energy

consumed in the process. The energy consumption

for traditional stripping processes is significantly

decreased when an adiabatic flash step is introduced

between the synthesis section and the recirculation

section.

Considering a grassroots urea plant with a

nameplate capacity of 3900 tpd, a steam saving of

70 kg/t final product would result in a cost reduction of

g

1 million annually, while a steam saving of 100 kg/t

would result in a saving of

g

1.5 million annually. This

calculation is based on natural gas priced at

US$4/million Btu and steam consumed at a pressure of

2.4 MPa and a temperature of 300°C.

The impact on investment costs for the above example,

although these are project- and region-specific, are

significant. The equipment costs for the adiabatic flash

concept would add up to some

l

2 million, but the

equipment cost reduction arising from not installing the

Figure 2.

LAUNCH MELT Flash design concept without a HP

scrubber.

Figure 1.

LAUNCH MELT Flash design concept with a HP scrubber.