NOVEMBER 2016

| WORLD FERTILIZER |

37

segregation of sulfur and

urea upon solidification.

The additive also serves

to bind the sulfur and

urea during the

solidification process.

ThioAdd additive does

not require any special

safety requirements and

can be handled in the

same way as any other

additive normally used in

the urea granulation plant.

In the first step, the

liquid sulfur is mixed with

concentrated urea

solution, the ThioAdd

additive, and any other

optional additives for trace elements or anti-caking

(Figure 1).

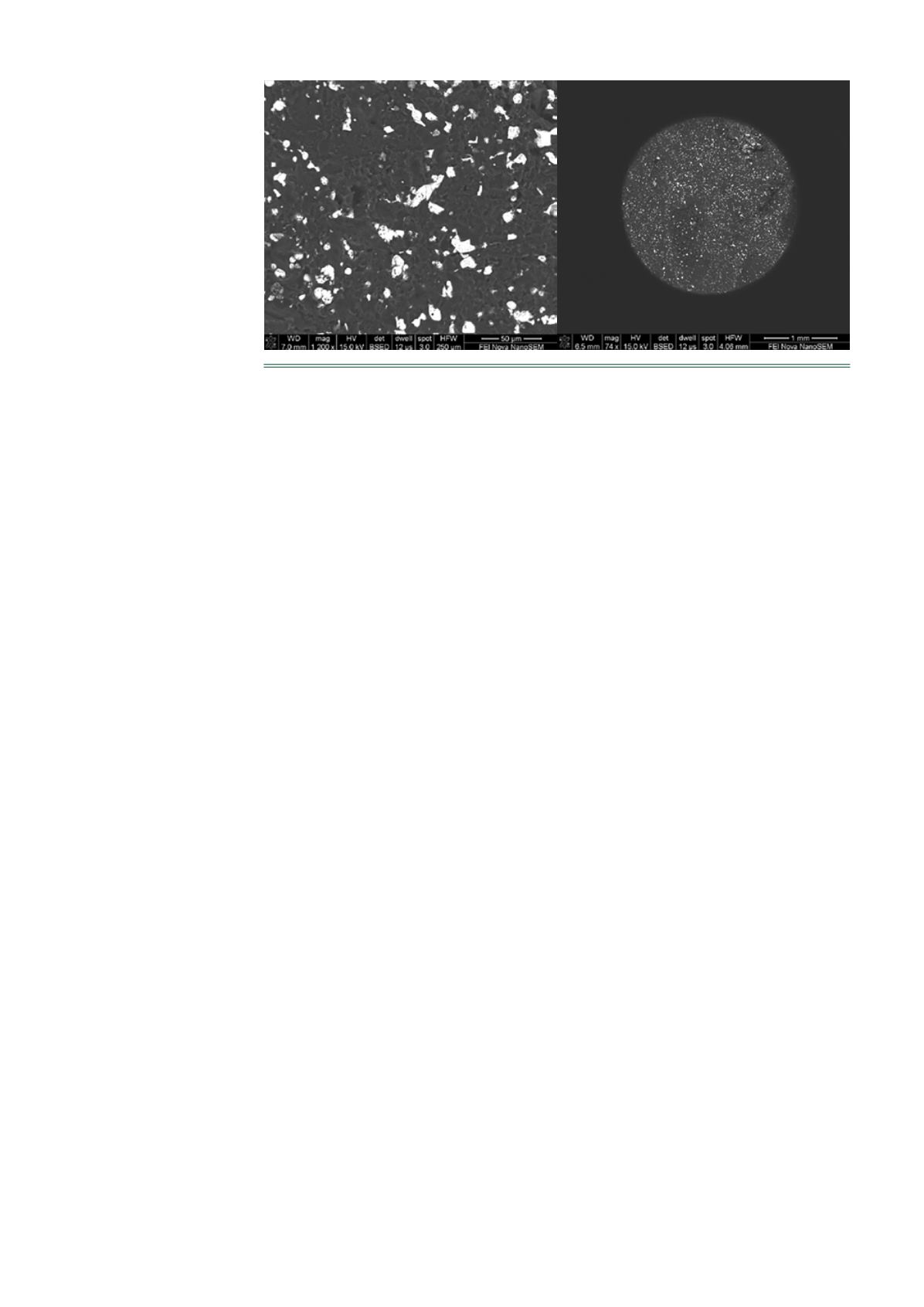

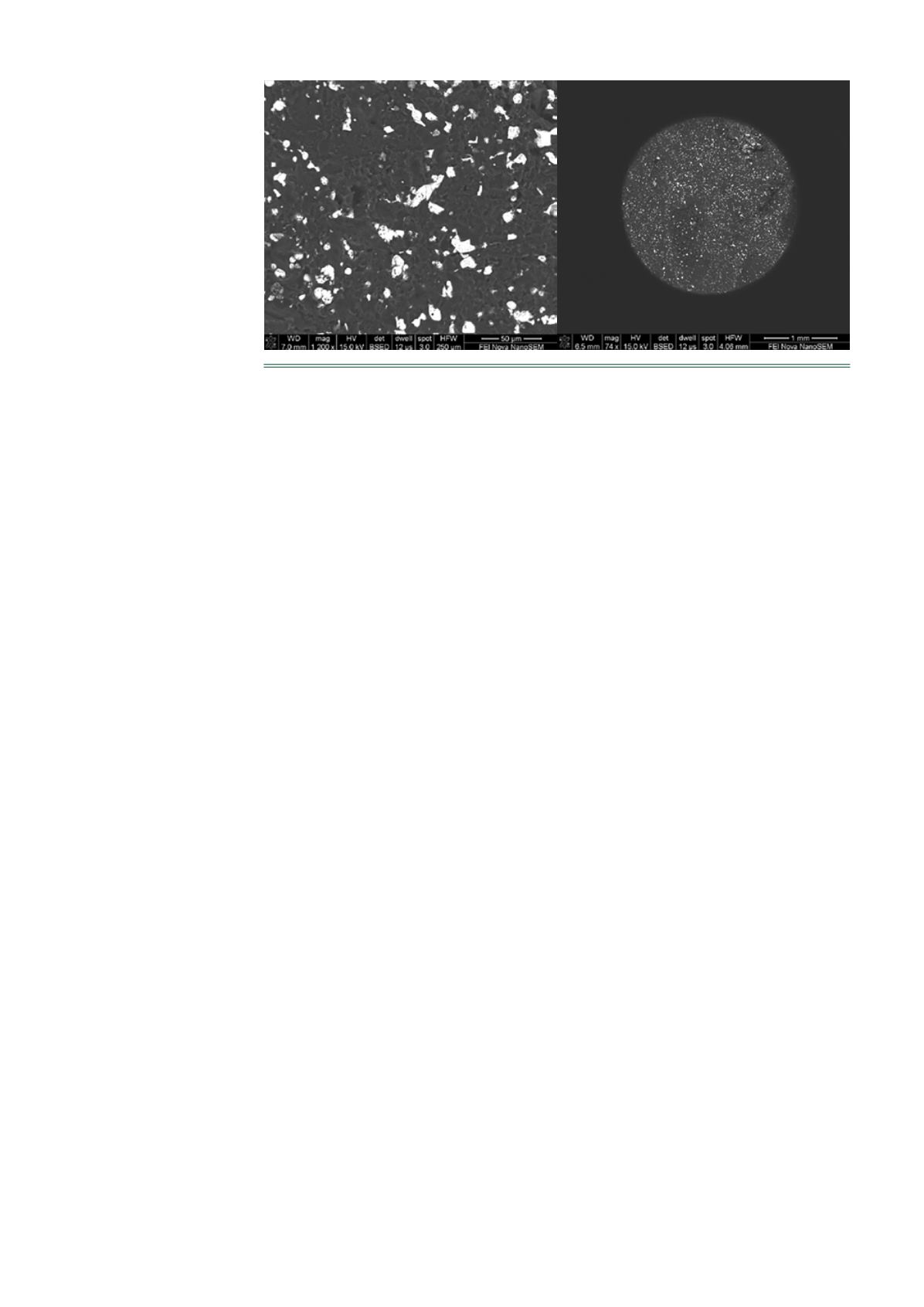

In the next step, a high-shear dispersion unit is used to

produce a uniform and stable dispersion of sulfur particles

in urea melt. This emulsion can be granulated to produce a

sulfur-enhanced urea containing sulfur particles that are

approximately <25

�

m (Figure 2).

From the dispersion unit, the sulfur-urea emulsion

goes to the granulator spray nozzles. The spray nozzles

used in a UFT fluidised bed plant are able to handle this

emulsion without modifications, and they require the

same range of operating conditions as used in urea

production. Erosion in the nozzles has not been found to

be a problem.

Implementation in a UFT fluidised bed

urea granulation plant

The UFT fluidised bed plant design has been proven to be

extremely flexible as evidenced by its usage in more than

60 plants located in all climatic regions.

Shell and UFT continue to carry out trials in UFT’s

batch operated pilot plant to optimise the process

conditions and product characteristics of Urea-ES. The

primary objective of the tests is to prove that the plant's

operating conditions will not change significantly from

current urea granule production.

The modifications required for a UFT fluidised bed

urea granulation plant to produce Urea-ES are shown in

Figure 3.

For new or existing plants, the following additional

units are required:

n

n

Sulfur dispersion unit (ThioMill).

n

n

Additive feed system (ThioAdd).

n

n

Recycle evaporation.

n

n

Sulfur feed system (upstream).

For existing plants, the following equipment must be

investigated:

n

n

Dust scrubber and recycle system (for urea/sulfur

slurry).

n

n

Bulk storage (additions for handling the new product).

Modifications required in a UFT fluidised

bed plant

In order to produce Urea-ES, a supply of elemental sulfur

and a sulfur unit are required. In most parts of the world,

the sulfur will be available in solid form. In this case, the

sulfur unit will need to consist of sulfur bulk storage, a

sulfur bulk handling system and a sulfur melter. The sulfur

unit does not have to be located near the urea

granulation plant. Sulfur melt can be piped, just like urea

melt, through heated piping. Due to the safety

precautions associated with sulfur dust, it is

recommended to locate the sulfur processing unit in a

safe location, and pump the sulfur melt to the urea

granulation plant.

In addition, there are significant differences in the dust

processing between granulation of plain urea and

granulation of a Urea-ES mixture. The Urea-ES dust, (e.g. in

the off-gas from the granulator or fluid bed coolers) will

contain sulfur. In a normal urea fluidised bed process, this

dust would be captured in the dust scrubbers, dissolved

and recycled to the evaporation unit of the upstream urea

synthesis plant. However, due to the sulfur content of

Urea-ES dust, recycling urea solution back into the

synthesis plant is not possible as sulfur components in the

solution could contaminate the condensate from the

evaporation unit, and from there the rest of the synthesis

unit (high-pressure synthesis and recirculation).

To avoid this contamination, a granulation plant

producing Urea-ES requires a dedicated evaporation unit

to process all the recycle streams from the urea fluidised

bed granulation plant. The condensate from this small

evaporation unit is used solely as make-up water for the

dust scrubbers and is not returned to the synthesis plant

or water treatment. UFT uses similar evaporation units in

plants that employ UFT’s proprietary ACT ammonia

emission reduction system.

While urea is fully water soluble, elemental sulfur is

insoluble in water. Therefore, the dust scrubbers and their

bleed must be modified to handle a liquid/solid solution.

This entails the elimination of ‘dead’ zones where solids

could accumulate and the installation of an improved dust

separation system in the scrubber. The horizontal

crossflow scrubbers, already applied in new UFT urea fluid

Figure 2.

Scanning Electron Microscopy of a 40-0-0-13S urea-ES sample.