66

| WORLD FERTILIZER |

NOVEMBER 2016

internally it needed to find a means to increase its

production output at the same time as addressing

product cooling practices threatening its quality.

The role of cooling

The requirements for product cooling are not new for the

fertilizer industry. Quite simply, product temperature

during storage is a critical quality parameter. It is generally

recommended that fertilizers be cooled so that the

resulting temperature is within 10 – 20°C of ambient

temperatures. These cooling parameters prevent moisture

migration that can lead to caking and product degradation.

Ammonium nitrate and calcium ammonium nitrate, as

special cases, are susceptible to phase change; they must

be cooled to a stable phase to prevent them from cycling

between phases as ambient temperatures vary.

The role of outdated technologies

For the past 50 or more years, the fertilizer industry has

used direct contact air coolers for final product cooling.

Rotary drum coolers began as the industry norm; however,

in the nitrogen fertilizer industry, fluid bed coolers –

thanks to their lower install capital cost, smaller footprint

and lower maintenance costs – have generally taken their

place. The operation of both rotary and fluid bed cooling

technologies requires high volumes of air. They depend

on largescale fans for air movement and scrubbers or

baghouses to meet ever more stringent emissions

requirements. Additionally, they have significant

footprints and can be difficult to accommodate and

install as part of plant retrofits.

In NAK Azot’s facility, when it reached the apex of its

dilemma in 2011, it was cooling its calcium ammonium

nitrate after granulation in three parallel fluid bed coolers.

The fluid bed coolers were employed to lower the

post-granulation temperature of the product to between

65 – 75°C. From here, the calcium ammonium nitrate was

moved into a rotary drum cooler for secondary cooling

and then transported to bulk storage. It was held in bulk

storage for three to four days until the temperature

further decreased to its target range of between

35 – 40°C. The company was investing in an expensive and

time-consuming process, and it was finding out the hard

way that, even with high-cost inputs, it was producing

low-quality outputs.

Unfortunately for NAK Azot, due to the high

temperature of the fertilizer going into bulk storage, its

product was highly susceptible to drawing in moisture and

caking as it went through its final stage of cooling. The

caked product was then reclaimed using two

Kratzer-Crane scrapers, which further degraded the

product and led to variable grain-size distribution and a

high percentage of fines. Despite its intensive efforts, Nak

Azot was getting low-grade product and, most

unfortunately, unhappy customers.

An alternative to incremental

improvements

Unwilling to let its market potential and commitment to

quality product pass by, NAK Azot started to explore

options to mitigate its caking problem and achieve better

quality control. Its first line of defense was to upgrade

one of its existing cooling components: the rotary drum.

It selected a replacement drum that allowed it to inject

anti-caking additives into its product batches before

sending them to bulk storage. For this incremental step

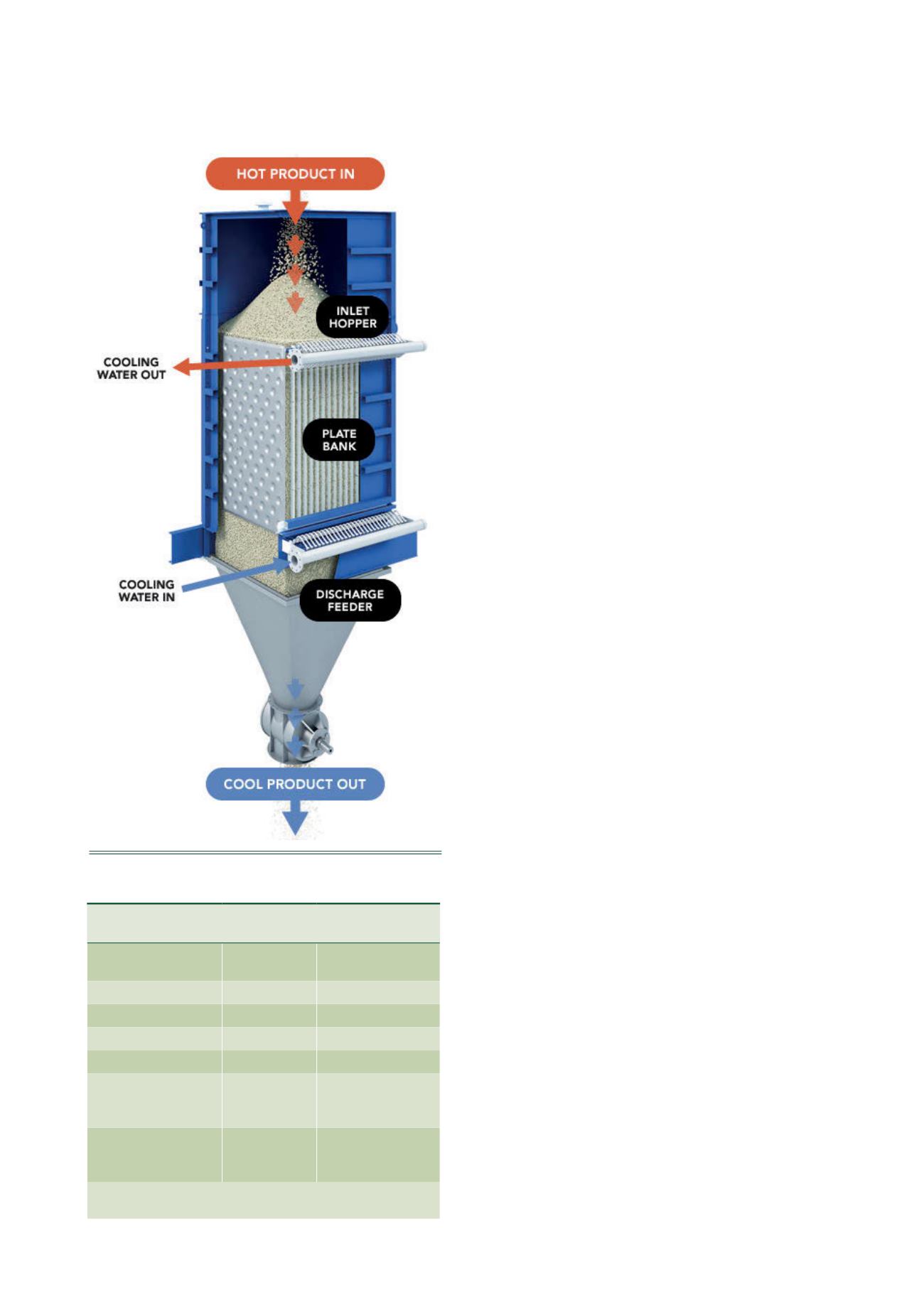

Table 1.

Total energy costs: fluid bed cooler vs Solex

product cooler

Fluid bed

cooler

Solex product

cooler

Fans (FD fan + ID fan)

(540 kW)

-

Air chiller*

540 kW -

Cooling water pump 500 kW 20 kW

Conditioned air blower -

45 kW

Bucket elevator (typ.)

Total power

consumption

-

1040 kW

20 kW

85 kW

Total energy cost/

year (US$0.10/kW.h –

8000 hr)

US$832 000 US$68 000

* Fluid bed chiller load is an average calculated based on mean

monthly day and night ambient location.

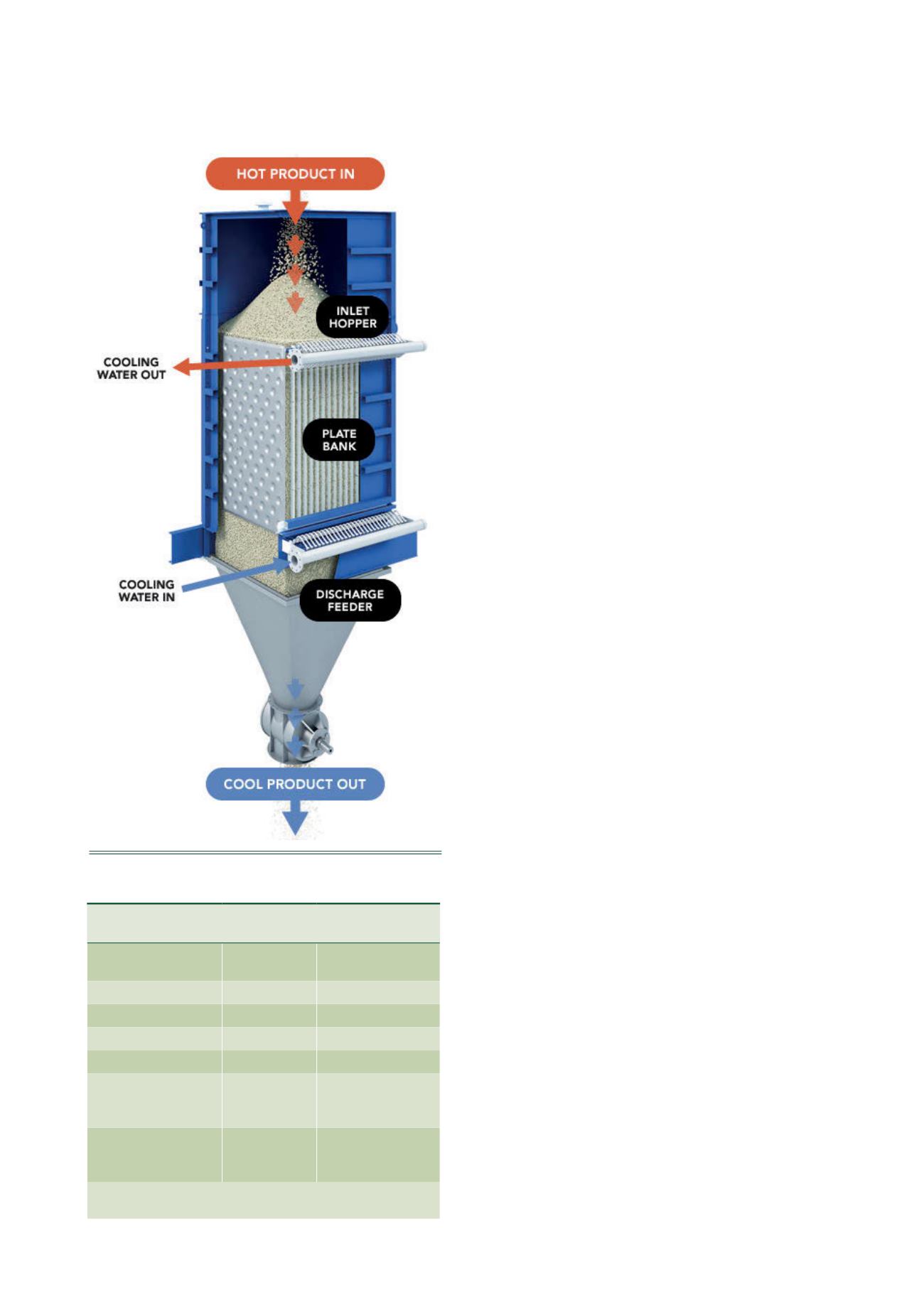

Figure 1.

Solex product cooler.