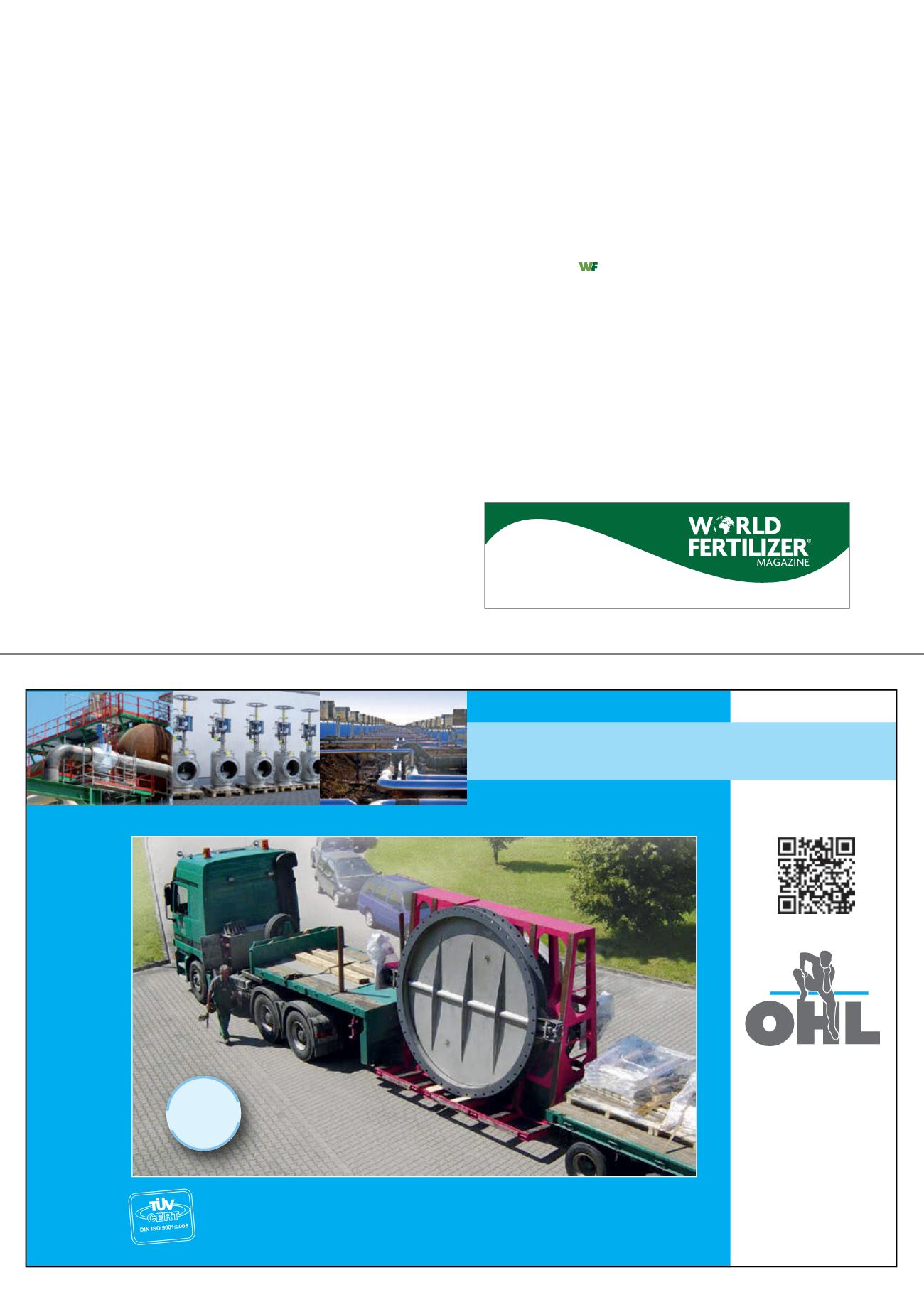

OHL Gutermuth

A control and shut off technique you can rely on.

Customized Valve Design

Others simply sell you a product –

we offer a solution.

OHL Gutermuth

Industrial Valves GmbH

Helmershäuser Str. 9+12

63674 Altenstadt/Germany

Phone +49 6047.8006-0

Fax +49 6047.8006-29

BEST VALVES

SINCE 1

867

MADE IN GERMANY

WE PROVIDE CUSTOMIZED SYSTEM SOLUTIONS

FOR GAS DESULPHURIZATION,

WITH THE EXPERTISE OF AN INTERNATIONAL LEADER IN INNOVATION.

RESULT:

BETTER RELIABILITY, BETTER ECONOMY.

side, which is preferred for gas cooling positions using

water, with a much lower volumetric flowrate, as the

cooling medium.

For plants where the sulfur content of the

hydrocarbon feedstock is high enough that amine

absorbers are the preferred choice for gas sweetening, the

same plate heat exchanger types can be used as for the

amine CO

2

removal process.

Methanation

The methanation converts the remaining CO and CO

2

in

the synthetic gas to methane through an exothermic

nickel catalytic reaction. An efficient methanation is

crucial since carbon oxides deactivate the catalyst in the

Haber ammonia reactor following the methanation

process. The incoming gas from the CO

2

absorber is

preheated with the exiting gas from the methanation

reactor. The methanation process may also be carried out

in several reactors with cooling between every step. Gas

cooling or interchanging in methanation processes where

temperatures are in the 250 – 450˚C range require welded

heat exchangers, preferably of plate type for maximum

efficiency and low maintenance.

Conclusion

Deciding which heat exchanger type is most suitable for

a specific position in an ammonia plant requires careful

consideration. The default choice in the industry is often

shell and tube heat exchangers without a proper

evaluation of the alternative options. Plate heat

exchangers offer much better thermal performance with

tighter temperature programmes, lower fouling levels

and a smaller footprint, and are often a more suitable

option for many positions. It is important to keep in

mind that where gasketed plate and frame heat

exchangers have limited resistance to pressure and

temperature, a welded shell and plate heat exchanger

can, in most cases, carry out the same duty as a shell and

tube heat exchanger but in a much smaller and more

efficient unit.

References

1. THONON, B., GRANDGEORGE, S., and JALLUT, C., 'Effect of

Geometry and Flow Conditions on Particulate Fouling in Plate

Heat Exchangers',

HeatnTransfernEngineering

(1999).

2. YOUSAF, S., 'Ammonia/Urea Plant rejuvenation',

Nitrogen+Syngasn

310

(2011).

3. LIMA, D. F. B., ZANELLA, F. A., LENZI, M. K., and NDIAYE, P.

M., 'Modeling and Simulation of Water Gas Shift Reactor: An

Industrial Case, Petrochemicals',

books/petrochemicals/modeling-and-simulation-of-water-gas-

shift-reactors-an-industrial-case (2012).

4. HAWS, R., 'Contaminants in Amine Gas Treating' (2009).

Register to

receive a regular copy