72

| WORLD FERTILIZER |

NOVEMBER 2016

article will briefly discuss the processes and the metallurgy of

the materials of construction. Emphasis will be placed on the

production of nitric acid, since this is where the greatest

potential for corrosion occurs and where the corrosion

resistance offered by the reactive metals – titanium and

zirconium – becomes very important. In this, titanium and

zirconium are used to prevent or minimise corrosion, resulting in

a long production life for the equipment.

Urea production

In the urea production plant, a stream of carbon dioxide is mixed

with a stream of ammonia and converted into urea (CO(NH

2

)

2

. As

this reaction takes place, no really corrosive conditions are

present in the system so no reactive metals are necessary to

combat corrosion. Most of the equipment at urea plants is either

carbon steel or a low-grade austenitic stainless steel, such as

304L or 316L. Once the urea is produced, it can be stored in

carbon steel vessels (protected by addition of corrosion

inhibitors) and then transferred to another part of the fertilizer

plant, where it can be combined with the nitric acid to

manufacture urea ammonium nitrate, which is used as a

nitrogen-based fertilizer.

Nitric acid production

Nitric acid can be produced in three different methods: a single

medium-pressure process, a single high-pressure process or a

dual-pressure process. Nitric acid is a strong, highly corrosive

acid, primarily used (roughly 80%) to make synthetic

nitrogen-based, commercial fertilizer. Commercial nitric acid

plants in the US are centred primarily in the agricultural areas of

the country: the Midwest, South Central and Gulf Coast. Most of

these plants are attached to a fertilizer plant to minimise the

transportation of the acid, reducing the cost and the potential

for acid spills. The acid produced for the fertilizer industry is in

the weak acid range of 50 – 65% strength.

In this stage, the nitric acid combines with the high

temperatures and pressures to develop a highly corrosive liquid

and gas stream. This is where the high corrosion resistance of the

reactive metals, titanium and zirconium, can be cost-effectively

used for the fabrication of equipment to enable a long life in this

aggressive environment. Cooler condensers and tail gas

pre-heaters must withstand the most aggressive environments in

the nitric acid plant, where temperatures are high and acid

concentrations vary as the gas is cooled and nitric acid

condenses onto surfaces at very high concentrations before

being diluted by the overall gas/liquid mixture.

Titanium and zirconium have been used in the nitric acid

industry for over 35 years. Titanium (Ti) and zirconium (Zr) exhibit

excellent corrosion resistance because of their ability to form an

adherent, dense, stable oxide layer on their surface. Once this

layer (TiO

2

or ZrO) develops, it effectively inhibits the access of

the corrosive to the underlying pure metal, stopping any further

corrosion from occurring. This mechanism is the exact opposite

to carbon steel, where iron oxide (red rust) forms and flakes off,

allowing the corrosive to have unlimited access to the

underlying metal and resulting in rapid, uniform corrosion.

Titanium is used for producing nitric acid in areas where

stainless steels have exhibited significant corrosion and titanium

has shown virtually no corrosion. Titanium offers excellent

resistance over the full concentration range of nitric acid at

temperatures below 212˚F. At higher temperatures, however,

titanium’s corrosion resistance is highly dependent on the purity

of the nitric acid. In hot, very pure solutions or vapour

condensates of nitric acid, significant general corrosion may

occur in the 20 – 70 Wt% range. However, the presence of even

a small amount of metallic elements (silicon, iron, chromium,

platinum, etc.) in the nitric acid can greatly extend the range of

use for titanium. Even titanium ions in the nitric acid (perhaps

from previous corrosion) can reduce the corrosiveness and

extend the range of use for titanium.

Every metal has its limits in terms of what chemistries it can

be effective in; and titanium is no different. As the nitric acid

concentration and temperature increases, the mechanism of

protection for titanium breaks down, resulting in an increased

corrosion rate. This necessitates the use of a more resistant

metal, zirconium. Zirconium is resistant to corrosion by nitric acid

even up to concentrations of 99 Wt% and temperatures

considerably over the boiling point. So, for weak acid areas at

lower temperatures, titanium can be used for cooler condensers

and tail gas preheaters. But, in the processes where higher

concentrations of nitric acid or higher temperatures are found,

zirconium becomes the metal of choice for corrosion-resistant

cooler condensers and tail gas preheaters.

Because of this excellent corrosion resistance in oxidising

conditions (where the oxide film can form), these reactive

metals are used in a wide variety of chemical plants as

corrosion-resistant equipment. In addition to nitric acid plants,

titanium has been successfully used for over 40 years in

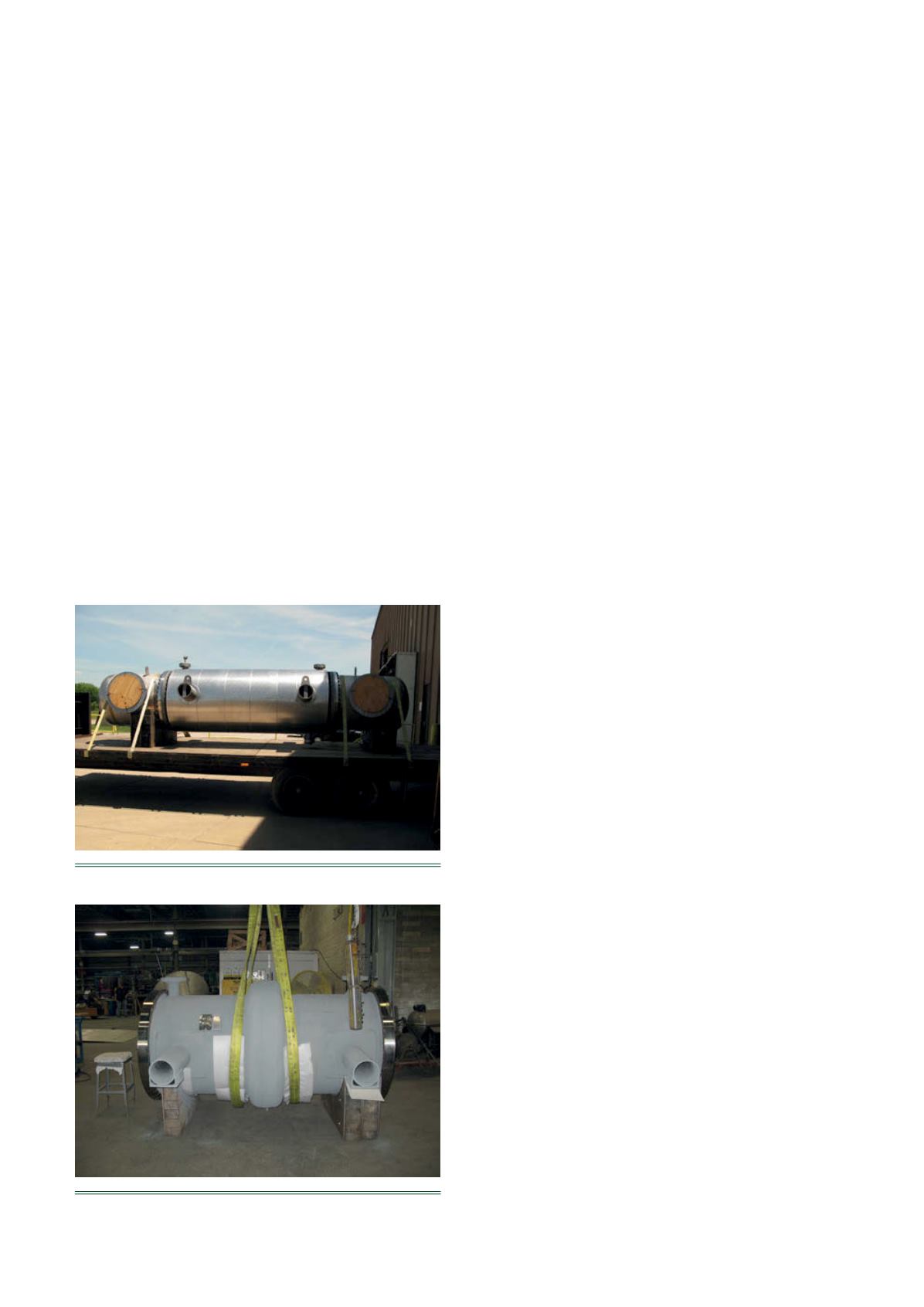

Figure 1.

Titanium cooler condenser.

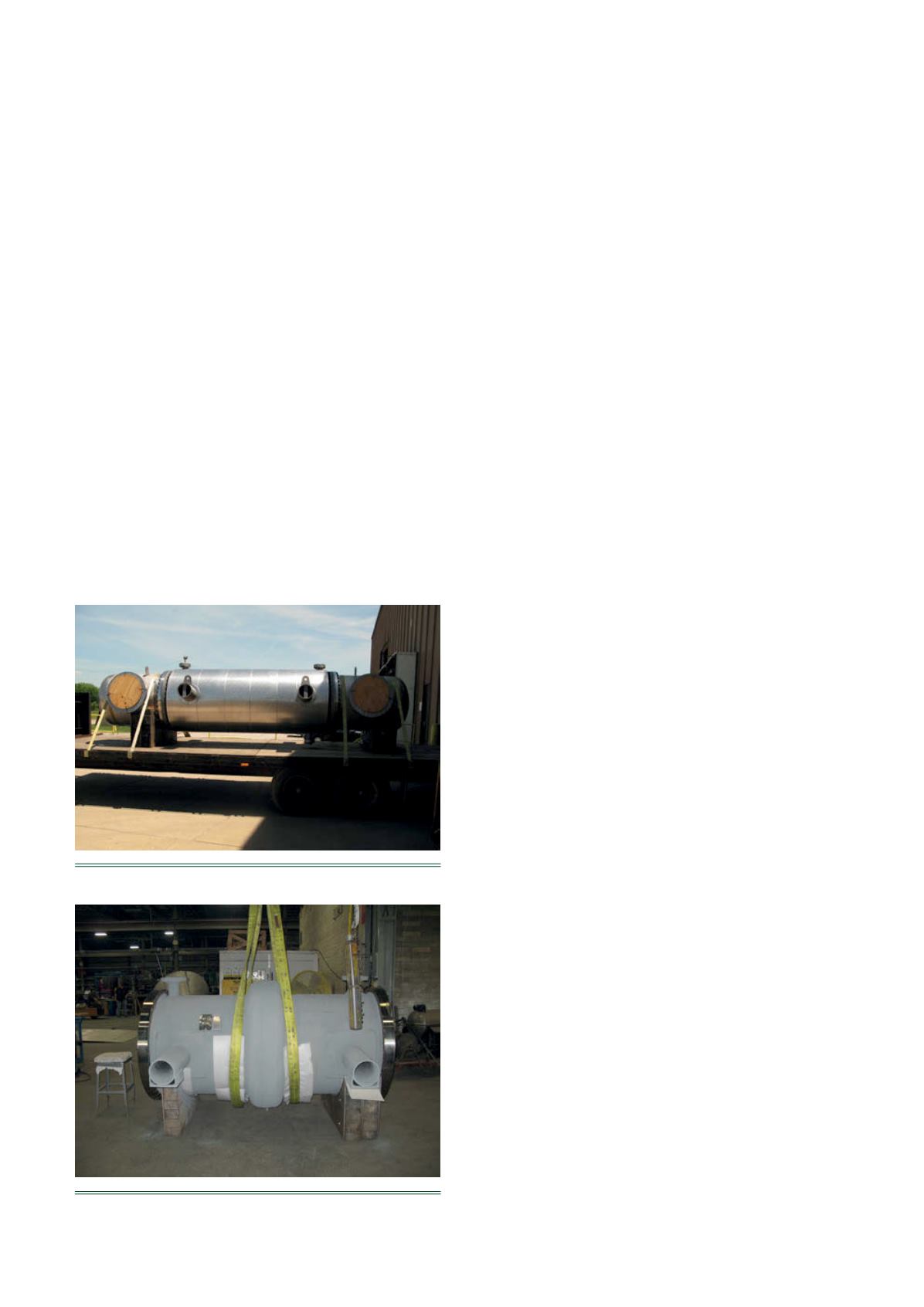

Figure 2.

Zirconium cooler condenser.