NOVEMBER 2016

| WORLD FERTILIZER |

67

forward, it was successful in reducing the

amount and thickness of the caking.

Unfortunately, NAK Azot was still faced

with the ultimate barrier to market growth:

it needed an effective, efficient and

reliable means to produce more fertilizer.

Within its current facility, this meant

increasing its cooling capacity. Standing at

this crossroad, it realised that incremental

investments would only ever yield

incremental gains. NAK Azot decided it was

time to seek out a game-changing solution

with the reputation to change both its

position and performance in the world

market.

In 2012, NAK Azot contacted Solex

Thermal Science Inc. and chose to

implement the company’s product cooler

that was already at work in nearly 150

fertilizer production facilities around the

world.

The solution

Solex first introduced its indirect contact

product cooling technology to the market

in the early 1990s. In a scenario not unlike

NAK Azot’s case, it was faced with the high

costs and limitations of retrofitting an

existing fertilizer facility with direct contact

cooling technology. Rather than accept the

available options, it developed a simple,

elegant heat exchange technology based on

indirect heat transfer that delivered and

surpassed expectations on multiple industry

challenges.

The product cooler combines the

science of mass flow with the thermal

efficiency of plate heat exchange design. In

the cooler, bulk solids pass in mass flow

through vertical banks of stainless steel

plates. Cooling water flows through the

plates to lower the temperature of the

material by conduction. The water is

circulated through the plates in

counter-current flow for enhanced thermal

efficiency. The indirect plate heat exchanger

design means air is not used in the cooling

process, a feature that reduces installation

and operating costs as well as guarantees

better environmental outcomes. A mass

flow discharge device controls the product

flow rate through the exchanger. The

product moves slowly, via gravity, through

the unit to create sufficient residence time

to achieve the required cooling. A level

control system ensures the product cooler

operates at its optimum configuration.

Key advantages

It can be integrated into nearly any facility

– new or mature – and used to cool full

ranges of fertilizers from urea granules and

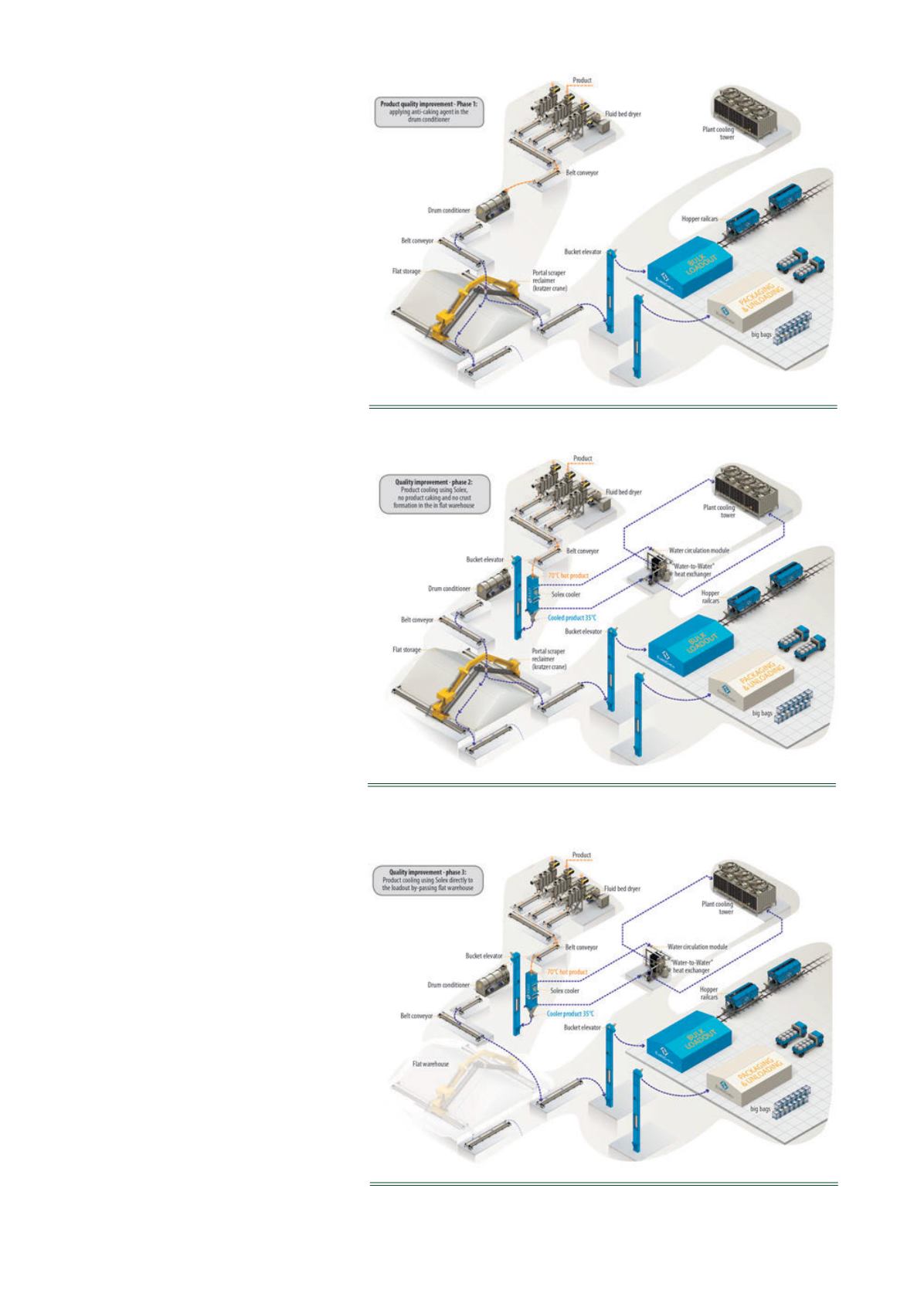

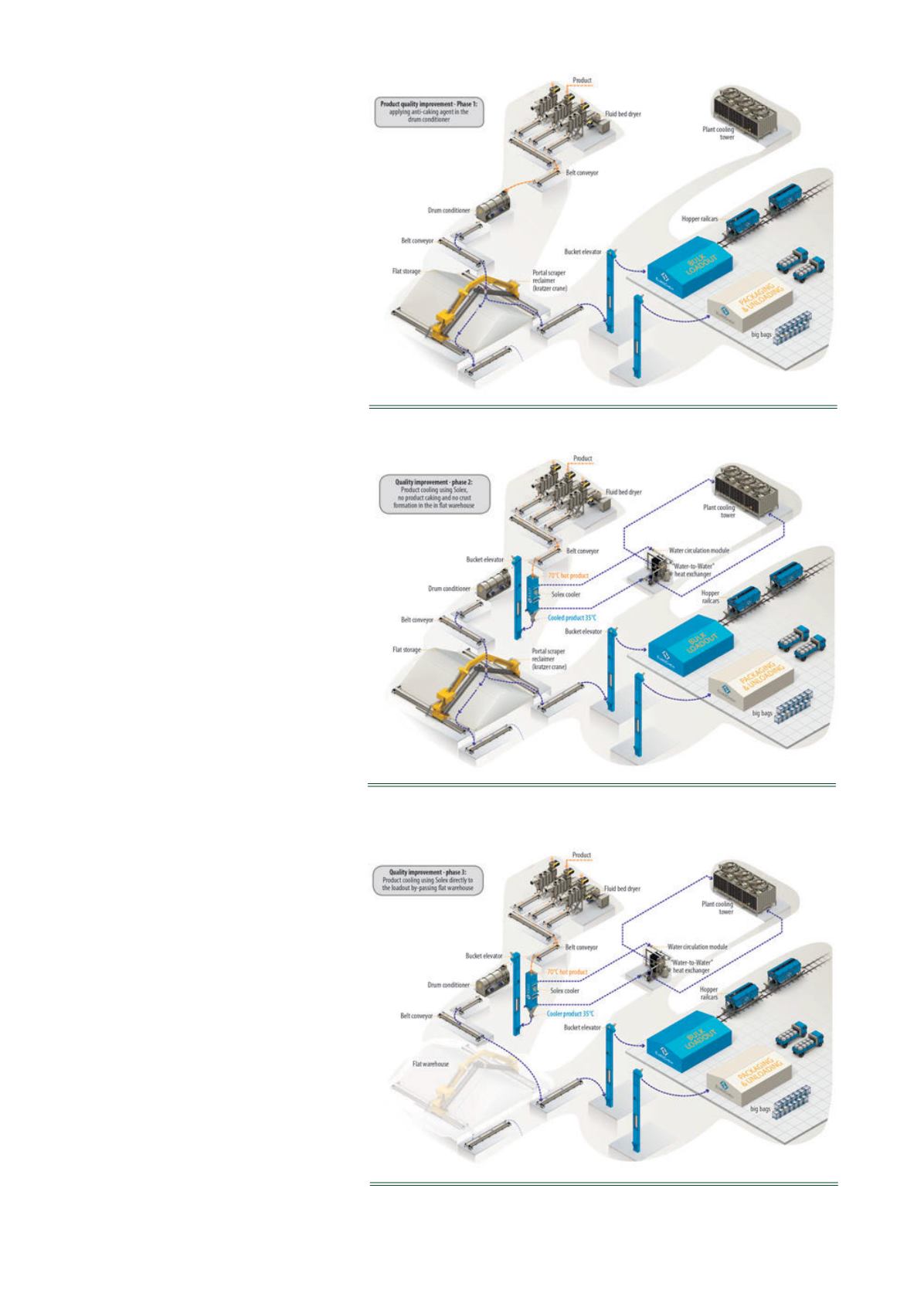

Figure 2.

Phase 1. Applying anti-caking agent in the drum conditioner.

Figure 3.

Phase 2. Product cooling using Solex, no product caking and no

crust formation in the flat warehouse.

Figure 4.

Phase 3. Product cooling using Solex directly to the loadout

by-passing flat warehouse.