56

| WORLD FERTILIZER |

NOVEMBER 2016

In addition to increasing plant capacity in order to benefit

from the effect of economy of scale, the requirements of an

increasing operational range from part-load to overload for the

waste heat boiler package can also be observed, for which the

equipment manufacturers have to guarantee the appropriate

process temperatures.

ARVOS | SCHMIDTSCHE SCHACK (previously known as

ALSTOM Power Energy Recovery GmbH) is a designer and

fabricator of relevant high-duty heat exchanger components and

packages for the chemical, petrochemical, refining and

metallurgical industry. It attributes the impact and dependencies

of special cost reduction measures to two focal points:

1.

Temperature control of the waste heat boiler package.

2.

Process gas cooler design.

Boiler package temperature control

Due to downstream hardware requirements, the process gas

outlet temperature of the SSH should not vary over the complete

operational range. In addition, the super-heated steam outlet

temperature should be achieved to ensure the overall process

efficiency.

In general, there are two different control concepts, which

differ in hardware layout and operational behaviour.

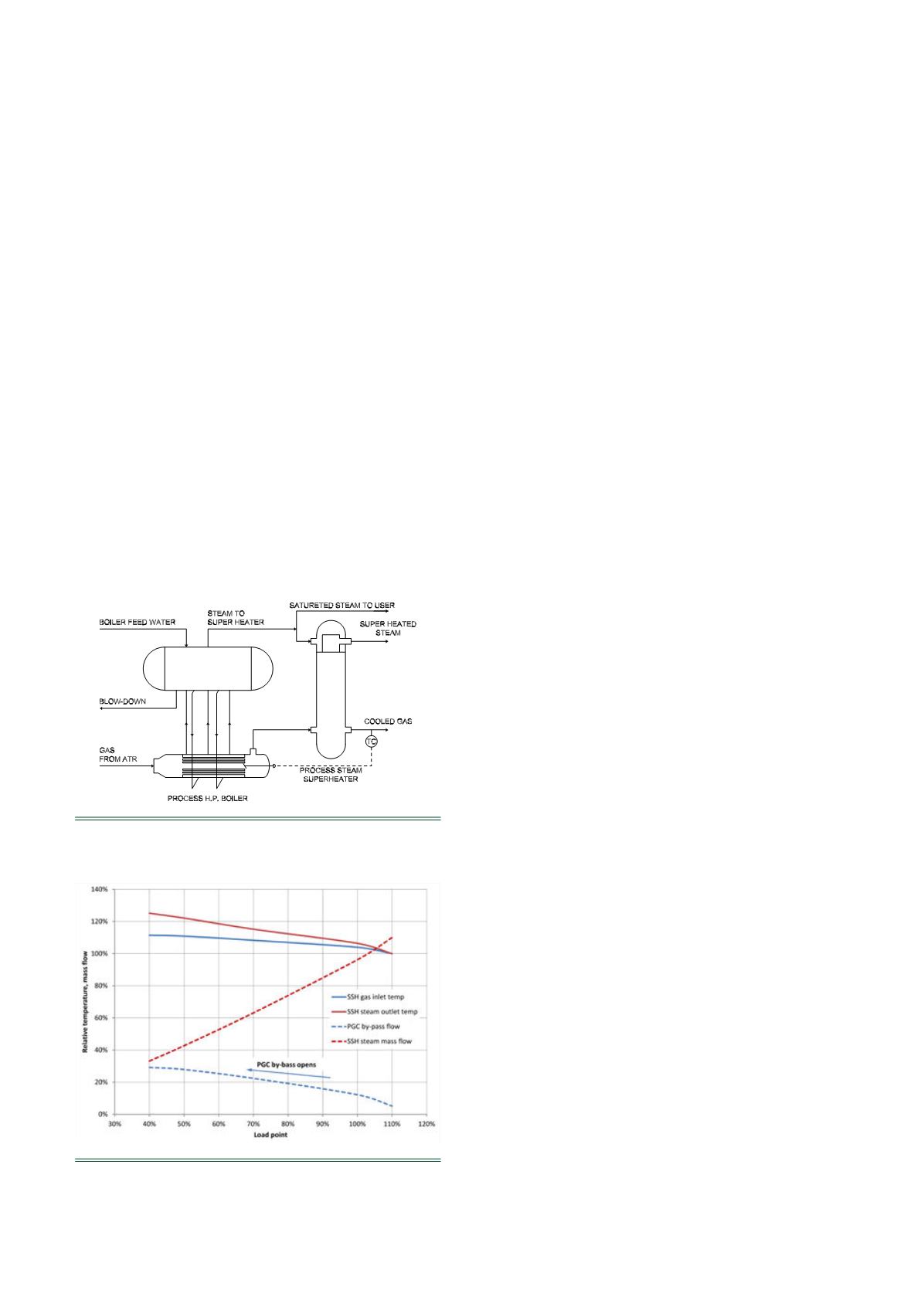

The simple control philosophy is equipped with a gas outlet

temperature control downstream to the SSH, as shown in Figure 1.

This temperature control activates the bypass of the PGC to

achieve the required process gas outlet temperature over the

complete operational range. The SSH itself has no bypass, which

has a positive effect on the capital and operational costs, as well

as on total availability of the package. Both heat exchangers are

designed for the maximummass flow and corresponding

maximum heat load (and potentially required over design by

customers). If the secondary reformer is operating in part-load

with reduced gas mass flow, the bypass of the PGC will be

adjusted to the actual operating conditions, but, for the SSH with

no bypass, this leads to varying process temperatures depending

on load conditions. Since the downstream process gas

temperature has to be constant over the operational range, the

gas inlet temperature to the SSH therefore has to increase with

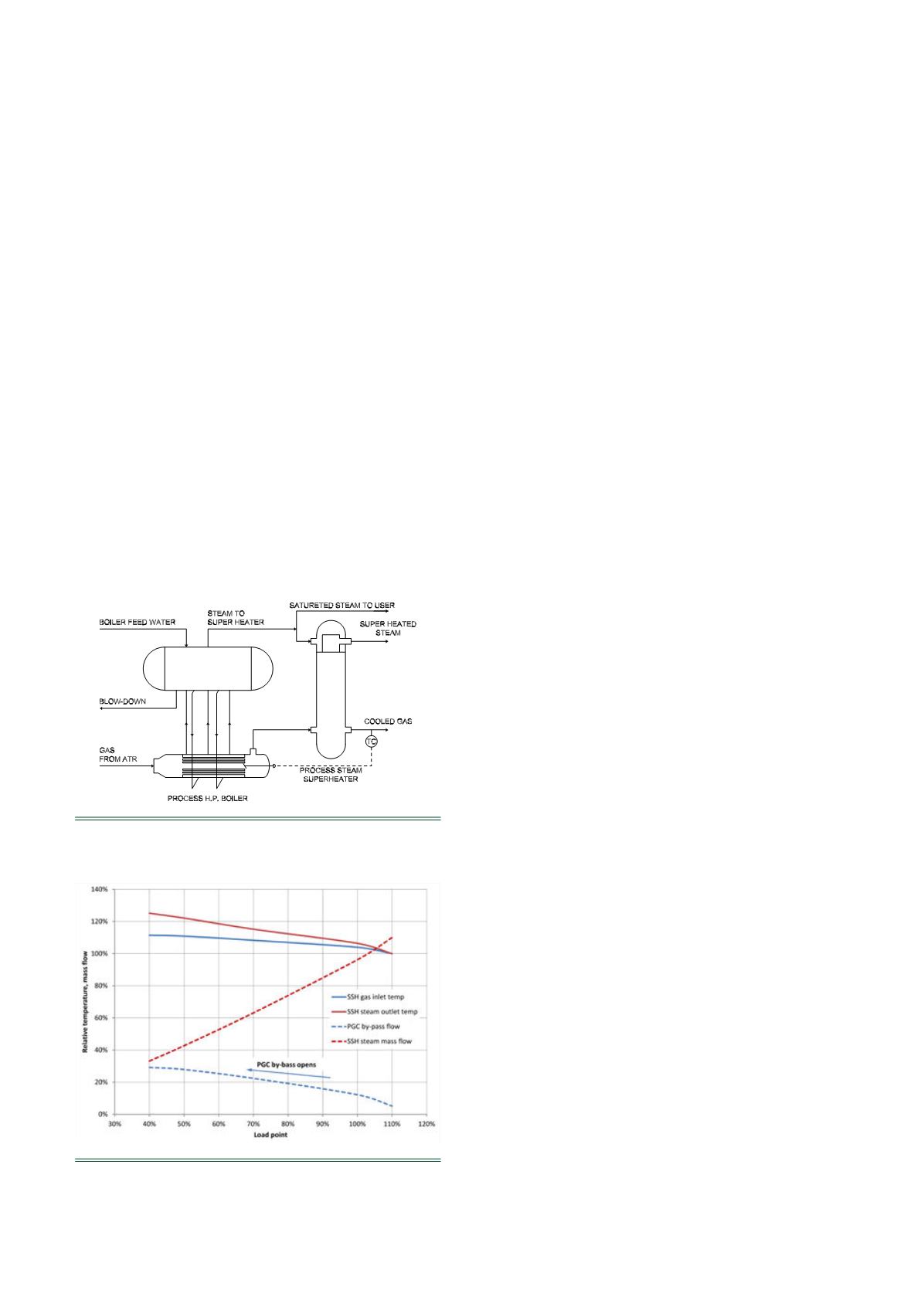

decreasing process gas mass flow (as shown in Figure 2). This

requires that the PGC bypass flow increases in low part-load

range, which results in a lower steam production of the PGC and

therefore a lower steammass flow to be super-heated by the

SSH. Consequently, the SSH steam outlet temperature increases

with decreasing load.

From an operational point of view, the decreasing steammass

flow might be acceptable depending on the requirement of the

steam consumers. But this control philosophy completely

changes the mechanical design of the SSH, since now the

part-load temperatures at the process and steam side are the

leading factors for the design temperatures of the apparatus. As

shown in Figure 2, the temperatures increase by 15% at gas side

and 25% at steam side compared to the nominal operation point.

This leads to higher wall thickness and/or material changes for

the gas and steam shell, as well as for the heating surface with

negative impact on thermal stresses and apparatus weight. In

addition, either the downstream steam system has to be designed

according to the highest steam temperature or the high steam

temperature has to be cooled down again by a continuously

operating spray water injection, which must use condensed steam

without impurities to protect the downstream steam system. A

further drawback is a large bypass for the PGC, which directly

impacts the PGC size and weight.

The benefits of this system are a simple control system and a

low-maintenance effort due to having only one bypass in the

system. However, the disadvantages described above clearly

compensate, or even overcompensate, this.

The second concept, which has been successfully installed by

the company at several ammonia plants for decades, includes a

temperature control of the PGC gas outlet that activates the PGC

bypass. In addition, the SSH is equipped with a bypass, which is

activated by a steam outlet temperature control (as shown in

Figure 3).

Figure 4 clearly shows that with this concept all process gas

and steam temperatures can be kept constant over the complete

operational range. In addition, the steam production of the PGC is

nearly linear with the process gas mass flow and load,

respectively.

The mechanical design temperature of the SSH at gas and

steam side are lower compared to the concept mentioned above,

which has a beneficial impact on the shell wall thickness, material

and thermal stresses. In addition, the downstream steam system

also requires lower design temperatures and the installation of a

spray water injection downstream so the SSH can be performed

as originally intended, namely as a safe guard. The ‘price’ to pay is

only a second bypass flap, which impacts the maintenance effort,

Figure 1.

P&ID of PGC package with simple temperature

control (concept 1).

Figure 2.

Temperature and bypass mass flow over

the operational range for simple temperature control

(concept 1).