88

| WORLD FERTILIZER |

NOVEMBER 2016

low-efficiency bubbling-type combination scrubber. The vent

gas was bubbled through the liquid section, where ammonia

and urea were removed. The removal efficiency of both

ammonia and urea was very low contact time, and low

turbulence limited urea particulate removal and vapour

Figure 10.

Scrubber retrofit in progress.

Figure 11.

Completed scrubber retrofit.

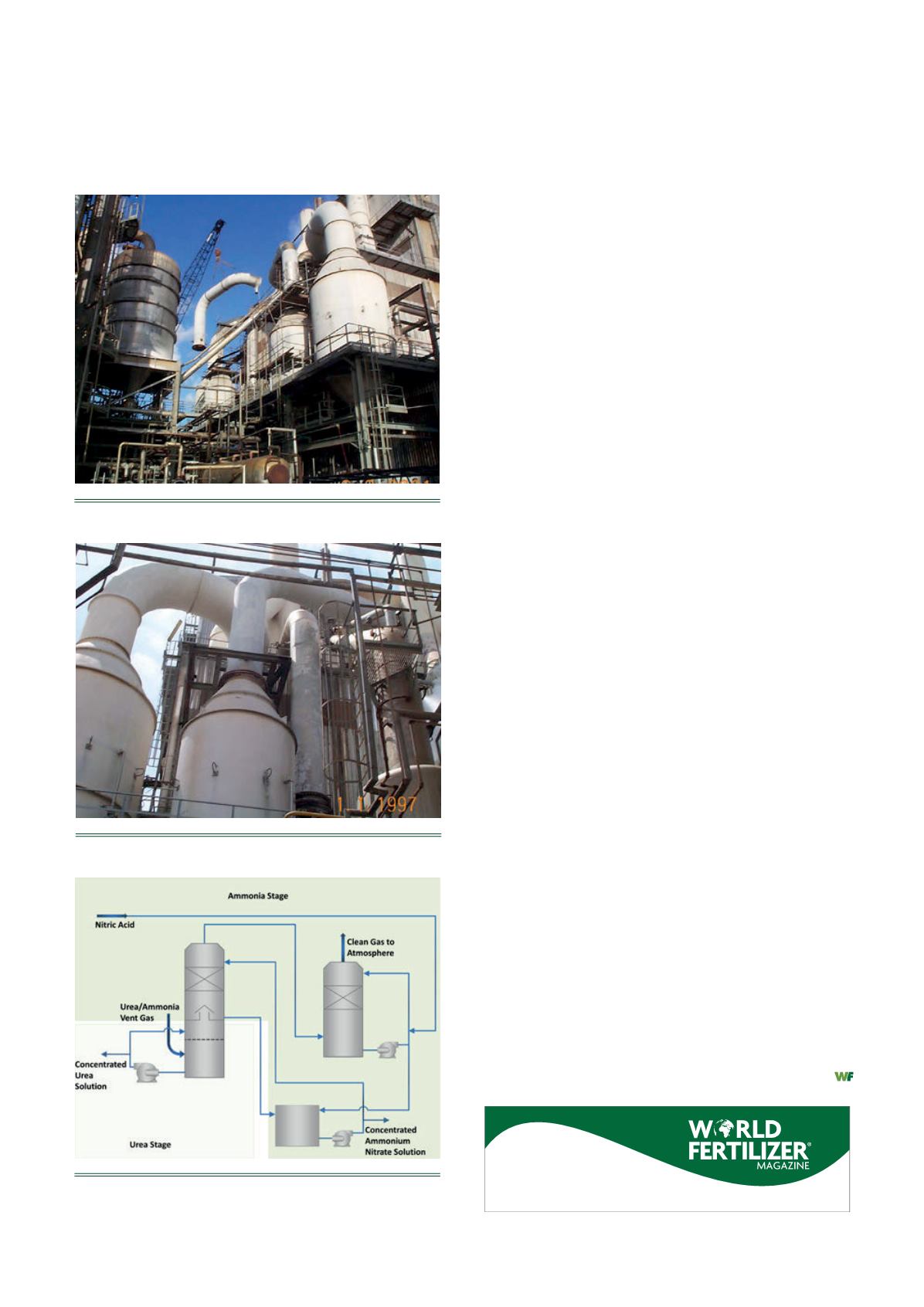

Figure 12.

Combined urea-ammonia removal and product

recovery with acid.

pressure at the high temperature reduced the ammonia removal

efficiency.

Macrotek was contracted to re-design the overall system

and improve removal efficiency for both urea and ammonia.

The low-efficiency, low-tech bubbling scrubber was retrofitted

to a two-staged plate and packed column absorber (Figure 9).

The first stage combined with upgraded controls resulted in a

significant improvement of urea collection and recovery. In

addition, the end-product was a more concentrated solution,

resulting in better product re-use and lower evaporator duty.

The ammonia removal retrofit, however, was more

challenging. The most common approach to remove ammonia

(particularly at elevated temperatures) is to use acid (most

commonly sulfuric or nitric). Due to limited acid availability and

cost, using acid for neutralisation was not a viable option.

Macrotek initiated an extensive evaluation of possible

options. After investigating modelling and design configurations,

the concept of using CO

2

to maintain pH and generate usable

byproduct was implemented. In addition, CO

2

vented to the

atmosphere was reduced (Figures 10 and 11).

Combined urea and ammonia removal using acid

A large fertilizer facility in Western Canada required a system

upgrade to improve ammonia removal in order to meet new

and more stringent regulations. The original installation

included the Macrotek MJ plate-tray scrubber for combined

urea and ammonia removal. The combination resulted in a

mixed byproduct and a more difficult process to re-use the

byproduct.

Macrotek was contracted to improve removal efficiency

and enhance byproduct recovery. A detailed evaluation and

process design was conducted to develop a design concept

and accomplish these objectives. It was common practice in

earlier plants to combine many vent sources and direct all to a

common scrubber for treatment. In this case, the large vent

source was mainly urea and several of the smaller streams were

mainly ammonia. The approach was to separate these sources

and to use the plate-tray scrubber for the urea and to design a

dedicated acid scrubber for the ammonia sources (Figure 12).

The final result was that emission levels for both ammonia and

urea were improved, reusable byproducts were generated and

optimum use of byproducts was realised (separate

concentrated urea and ammonium salt); all objectives were

achieved.

Conclusion

Different control technologies are available for the control of

urea and ammonia from various vent sources. Macrotek’s

approach is to evaluate all considerations and custom design a

fit-for-purpose system that will reduce emissions to the most

stringent levels and generate a usable byproduct. In most cases,

added benefit is realised by using dilute wastewater streams as

makeup water. This reduces the load to the wastewater plant or

evaporator while generating a concentrated, usable product.

Register to

receive a regular copy