NOVEMBER 2016

| WORLD FERTILIZER |

87

Similarly plant water or a dilute waste liquid stream can

be used as makeup water, which will convert a wastewater

stream to a usable concentrated urea solution.

Venturi scrubber

The Macrotek annular throat venturi scrubber (model MVA) is

designed for applications requiring high removal of

sub-micron particulate (Figure 5). Water is introduced onto an

annular disc through a central pipe, which also acts as the

disc support (Figures 6 and 7). The supply pipe and water

distribution cap have large openings, which allows the

distribution of recycled water with minimal possibility of

plugging. Water flows outward on the disk to the annular

throat, creating consistent water curtain and optimum

shearing and turbulent action to maximise urea capture. At

the throat, the relative velocity difference between the gas

and water is highest. The water is sheared into tiny droplets

that collect entrained particulate by impaction. Water

droplets are agglomerated and collected by the downstream

high-efficiency mist eliminator in the separator vessel

(Figure 8). The chevron offers maximum droplet removal at

minimal pressure drop and maximum resistance to build-up.

An automated mist eliminator wash system is incorporated

into the design to clean the mist eliminator periodically in

order to prevent build-up and an increase in pressure drop.

Process control

Optimum pressure drop is maintained at the throat section

by raising or lowering the annular disk to increase or decrease

the gap at the throat section. Adjustment of the throat gap

control can be manual or automatic.

Vertical movement of the disc in the converging throat

provides a means for varying the area of the annulus over a

very large range. This allows flexibility and capacity to adjust

for varying flow conditions. Furthermore, increasing the

pressure drop will also increase the removal efficiency and

the removal of smaller particulate.

Combined urea-ammonia removal and

product recovery

Many applications and emission sources, such as granulators,

require removal of both urea and ammonia. A combined

approach is desirable for these applications. This

custom-designed, fit-for-purpose approach will allow the

waste byproduct to be used as the reagent while recovering a

usable byproduct. For these applications, a two-stage process

is implemented. The first stage includes urea removal by

either a plate-tray scrubber or venturi scrubber and the

second stage includes ammonia removal and ammonium salt

generation. Both stages recover valuable byproduct.

In addition, dilute waste liquid streams can be

incorporated to increase concentration and convert these

waste liquid steams to usable solutions.

Case studies

Combined urea and ammonia removal using waste

CO

2

as neutralising reagent

A large multi-national fertilizer plant in the Caribbean was

mandated to reduce urea and ammonia emissions from its

granulator exhaust. The original installation included a

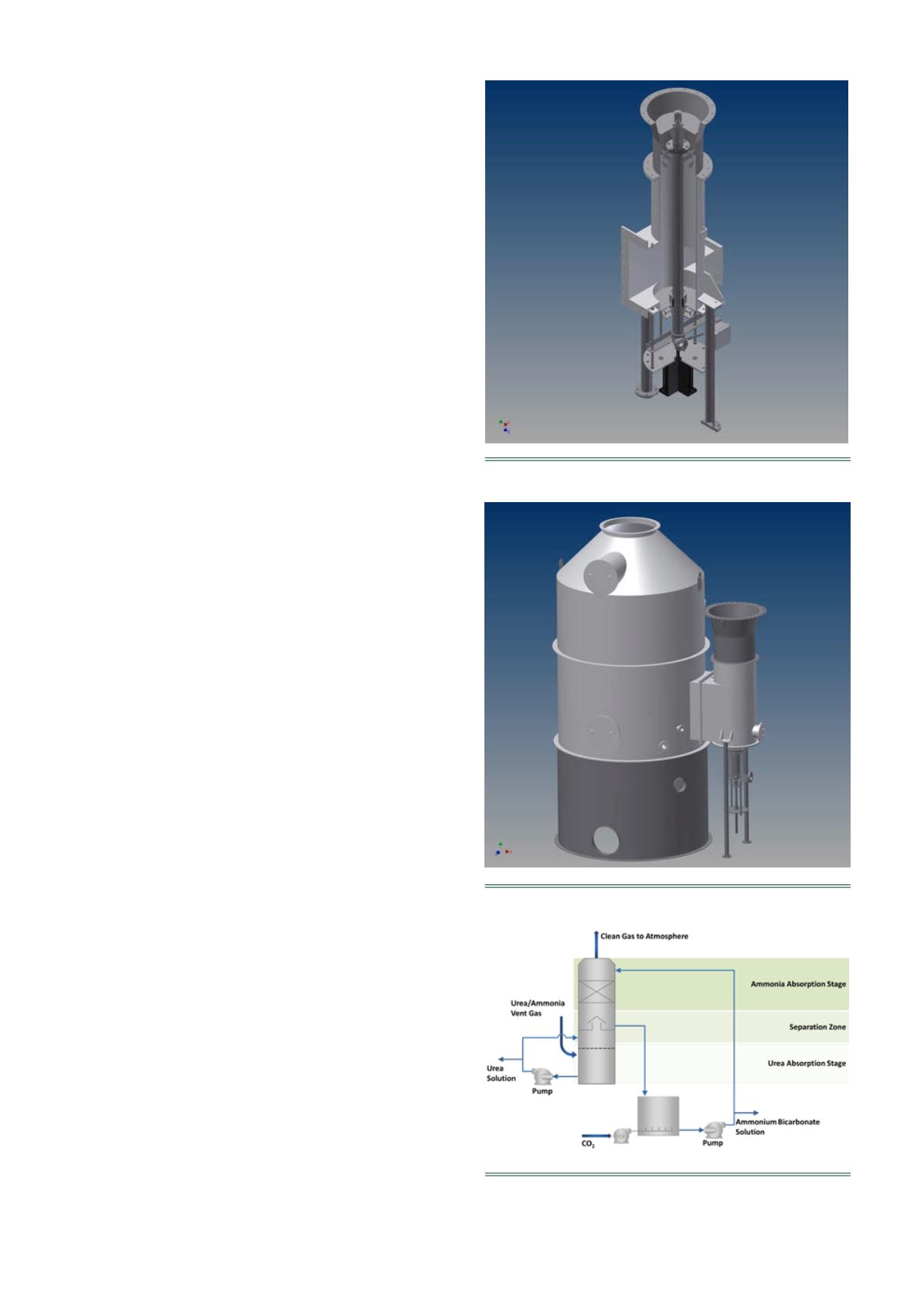

Figure 9.

Combined urea-ammonia removal and product

recovery with CO

2

.

Figure 8.

Model of MVA and separator vessel.

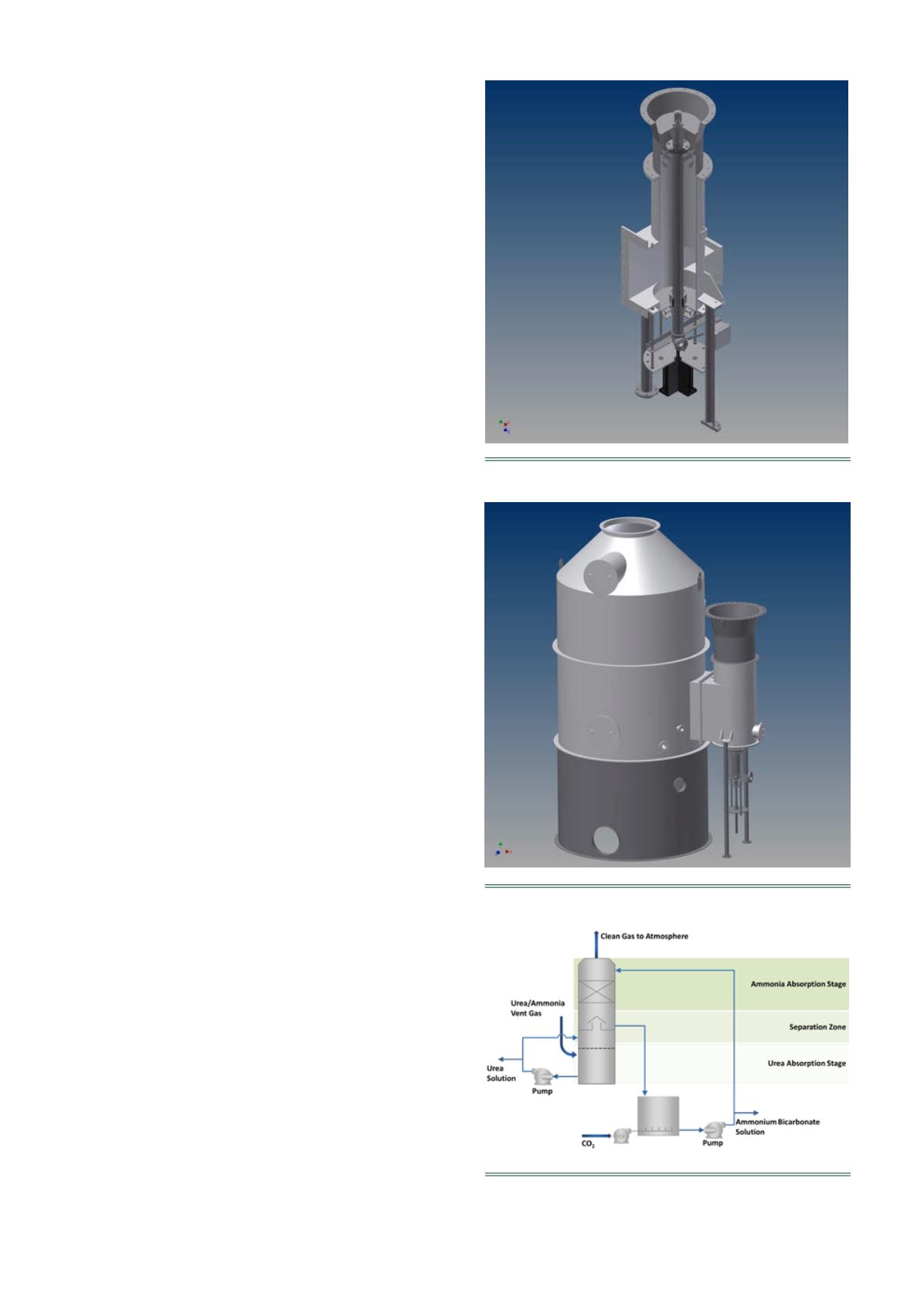

Figure 7.

Cut-out of MVA.