84

| WORLD FERTILIZER |

NOVEMBER 2016

This article will describe several applications for the

treatment and control of ammonia and urea emissions,

including CO

2

injection and acid neutralisation. In all cases,

the objective is to combine and control emissions, and

generate a usable byproduct.

Ammonia and urea production and

emission sources

Ammonia (NH

3

) is produced by reacting the nitrogen in the air

with hydrogen from a hydrocarbon source, most commonly

natural gas. During the steam reforming process of natural gas,

carbon dioxide (CO

2

) is a generated waste byproduct, which is

often vented to the atmosphere.

Urea (NH

2

CONH

2

) is synthesised by reacting CO

2

and

liquid ammonia to produce ammonium carbamate, which is

dehydrated into urea. The urea is concentrated and sent to a

prill tower or granulator to produce solid urea.

Major ammonia emission sources originate from the

reaction process as well as from ammonia tank farms, while

major urea dust emission sources originate from the prill

tower or granulator.

Why remove ammonia and urea?

Ammonia is a colourless alkaline gas that has an odour

threshold between 5 – 50 ppm (OSHA). Not only is the odour

pungent, but it is also toxic if inhaled. Furthermore, ammonia

is corrosive to skin, eyes and the respiratory tract. Under

certain conditions, ammonia is flammable. It is very soluble in

water, forming ammonium hydroxide (NH

4

OH). Urea is a white

organic compound (particulate) and also very soluble in

water. Urea is also an irritant to skin, eyes and the respiratory

tract and is hazardous in case of ingestion or inhalation.

It is clear that the removal of ammonia gas and urea dust

from emission to the atmosphere is important for the

environment and human health. In addition, ammonia and

urea are also valuable products and it is therefore favourable

to optimise recovery for reuse.

Scrubber technologies and process control

Selection of the optimum control technology is dependent

on many factors, such as contaminant properties, required

removal efficiency, reagent, etc. In this section, three different

control technologies are summarised. For gases such as

ammonia, packed-bed scrubbers offer optimum mass transfer

due to the increased surface area provided by the packing

media. For readily soluble particulate, such as urea, plate-tray

scrubbers offer extended contact time of the liquid and gas

at each stage for dissolution of soluble salts into the

recirculating liquid, while venturi scrubbers achieve collection

of particulate by inertial impaction.

Packed bed for optimum mass transfer and

absorption of ammonia

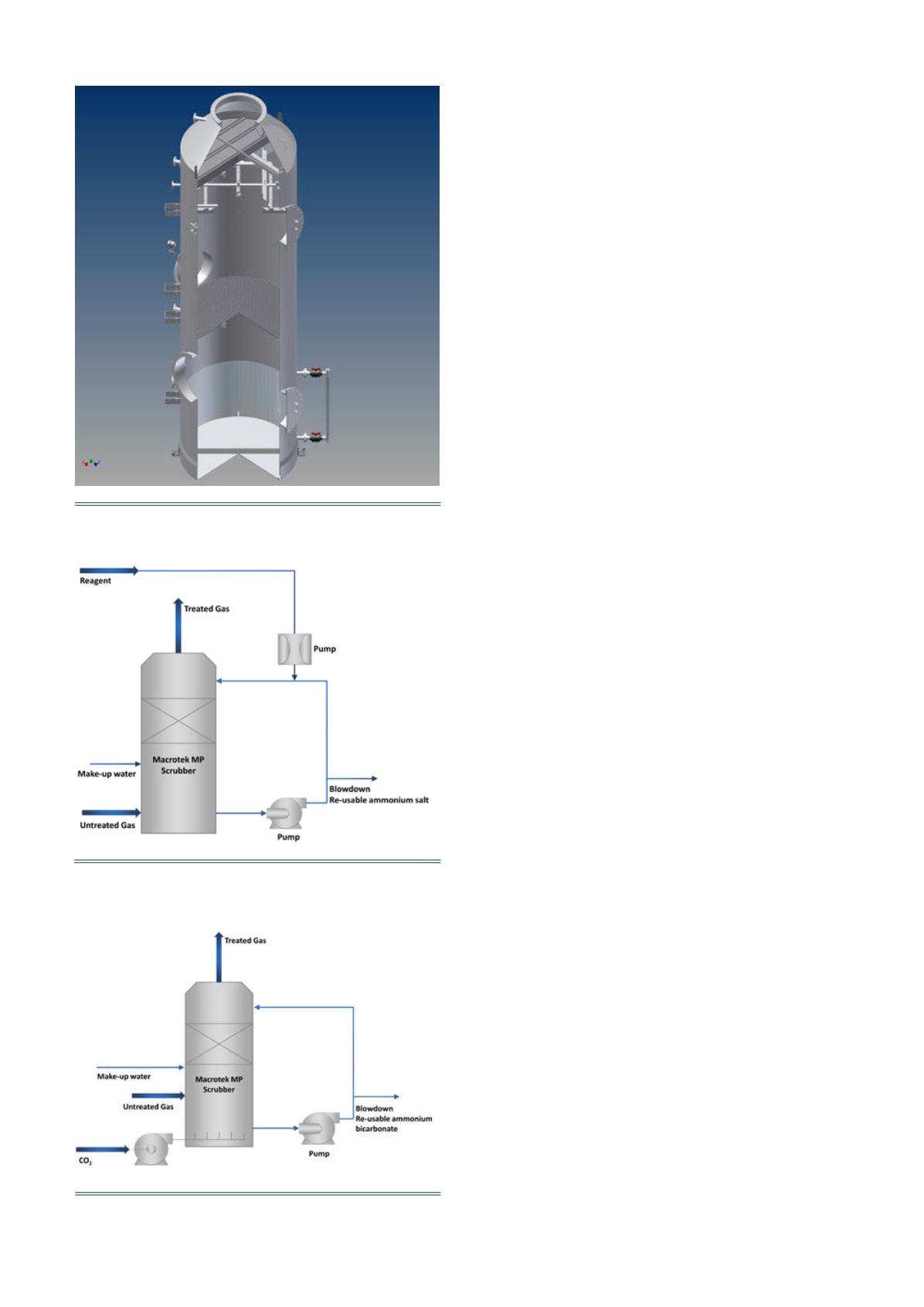

The Macrotek packed-bed scrubber (model MP in Figure 1)

uses a vertical counter-current design for the highly efficient

absorption of gases (Figure 2). In the vertical counter-current

design, gas flows upward while scrubbing liquid flows down

through a liquid distributor. The scrubber uses random

packing for enhanced mass transfer and absorption of gases.

A high-efficiency mist eliminator removes entrained liquids.

This is an essential step in the overall performance of the

Figure 3.

Removal of ammonia with carbon dioxide.

Figure 1.

Model of MP.

Figure 2.

Process flow diagram of Macrotek MP

packed-bed scrubber.