86

| WORLD FERTILIZER |

NOVEMBER 2016

scrubber system. A regulated amount of reagent will be mixed

in the re-circulating liquid to maintain a set-point pH level.

The contaminant in the gas will react with the reagent of

choice, forming ammonium salts. The reaction product will

be carried in the re-circulating liquid. Discharge of

concentrated usable ammonium salt is regulated by set-point

conductivity or density monitoring.

Process control with acid reagents

Nitric acids and sulfuric acids are most commonly used to

neutralise the ammonia gas after absorption into the scrubbing

liquid to form ammonium nitrate (NH

3

NO

3

) or ammonium

sulfate ((NH

4

)

2

SO

3

), respectively. The overall equation for each

reaction is shown in Equation 1 and Equation 2. The reagent is

added to maintain a pH set-point. Conductivity is continually

measured and is used to maintain a set-point concentration by

continually bleeding concentrated, usable ammonium salt

solution. Both (NH

4

)

2

SO

3

and NH

3

NO

3

are usable byproducts,

which reduce waste generation.

1. Ammonia removal with nitric acid:

NH

3(g)

+ HNO

3(aq)

→

NH

4

NO

3(aq)

2. Ammonia removal with sulfuric acid:

2 NH

3(g)

+ H

2

SO

4(aq)

→

(NH

4

)

2

SO

3 (aq)

Plant water or a dilute waste liquid stream can be used as

makeup water. This will provide for additional benefits by

converting a wastewater stream, which may need to be

evaporated, to a usable concentrated ammonium salt solution.

Process control with carbon dioxide

Using CO

2

to control ammonia provides a double benefit by

reducing CO

2

emissions into the atmosphere and generating a

usable byproduct. Carbon dioxide gas is bubbled through the

recirculating liquid (Figure 3) after ammonia absorption into

the scrubbing liquid to form ammonium bicarbonate. The

overall equation of this reaction is shown in Equation 3.

Since the CO

2

and NH

3

are in the gas phase, decreasing

the process temperature will increase the solubility and

therefore concentration, which is favourable for the reaction.

Furthermore, decreasing the temperature decreases the Gibbs

free energy and the reaction is thermodynamically more

favourable. In addition, the production of ammonium

bicarbonate is more thermodynamically favourable than

ammonium carbonate at all temperatures as governed by the

Gibbs free energy at standard conditions.

3. Ammonia removal with carbon dioxide:

2NH

3(g)

+ H

2

O + CO

2(g)

→

NH

4

HCO

3(aq)

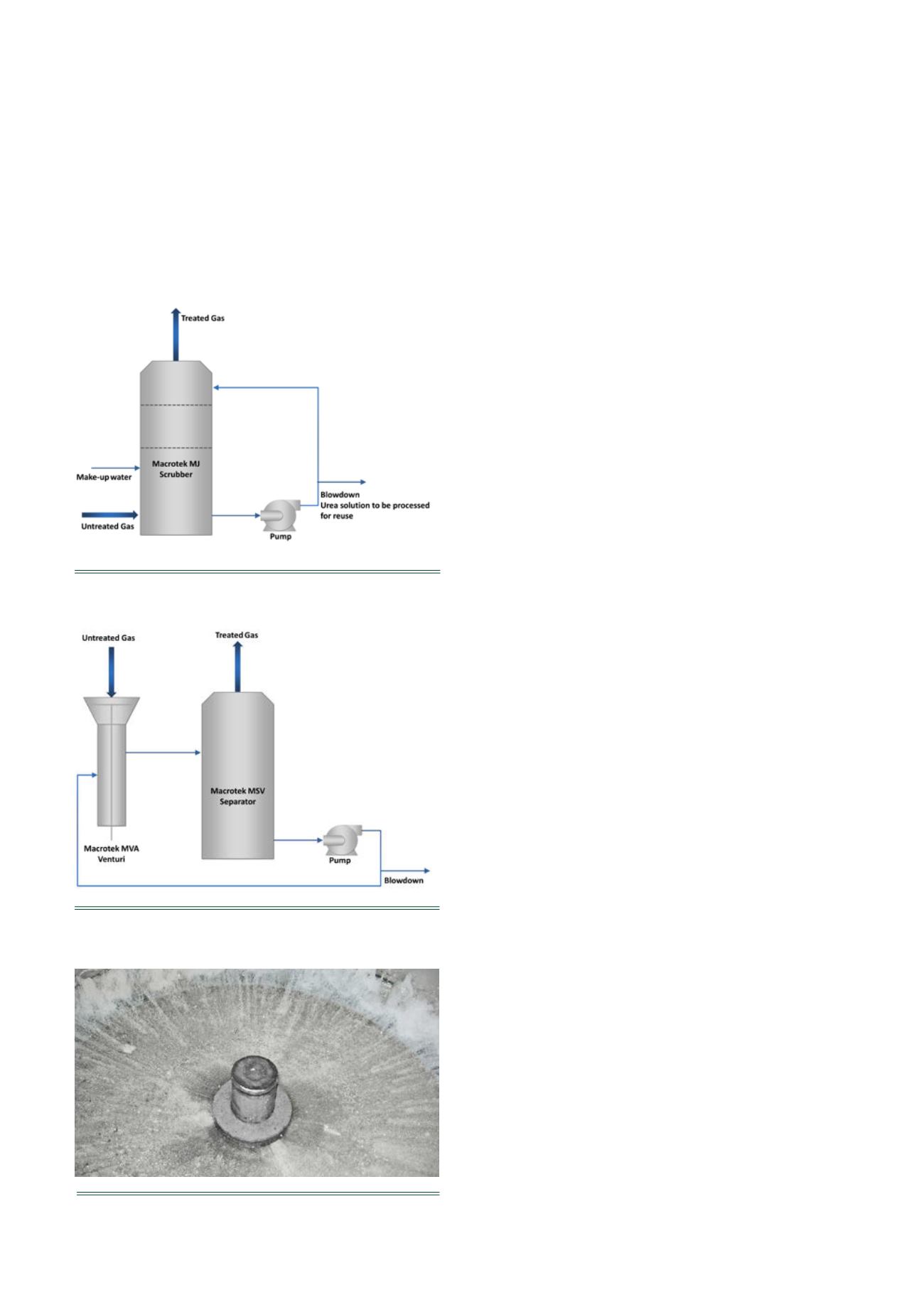

Plate-tray scrubber for urea collection

The Macrotek plate-tray scrubber (model MJ) has been

successfully applied to a diverse range of industrial

emissions (Figure 4). The system has no moving parts and

scrubber internals are readily accessible for routine

maintenance or replacement. High efficiencies for

particulate collection and mass transfer rates for gas

absorption are achieved at low pressure drops and low

liquid consumption rates. The scrubber uses the

impingement plate design, where gas to be scrubbed jets

upward through a flooded perforated plate colliding with a

wetted target directly above each orifice. The highly

turbulent action of these jets creates a uniform gas-liquid

contact zone for maximum urea capture.

Process control

As the urea in the untreated gas absorbs into the scrubbing

liquid and the urea concentration increases, a density

set-point is maintained by continually bleeding concentrated

urea solution back to the process for re-use.

Figure 4.

Process flow diagram of Macrotek MJ plate-tray

scrubber.

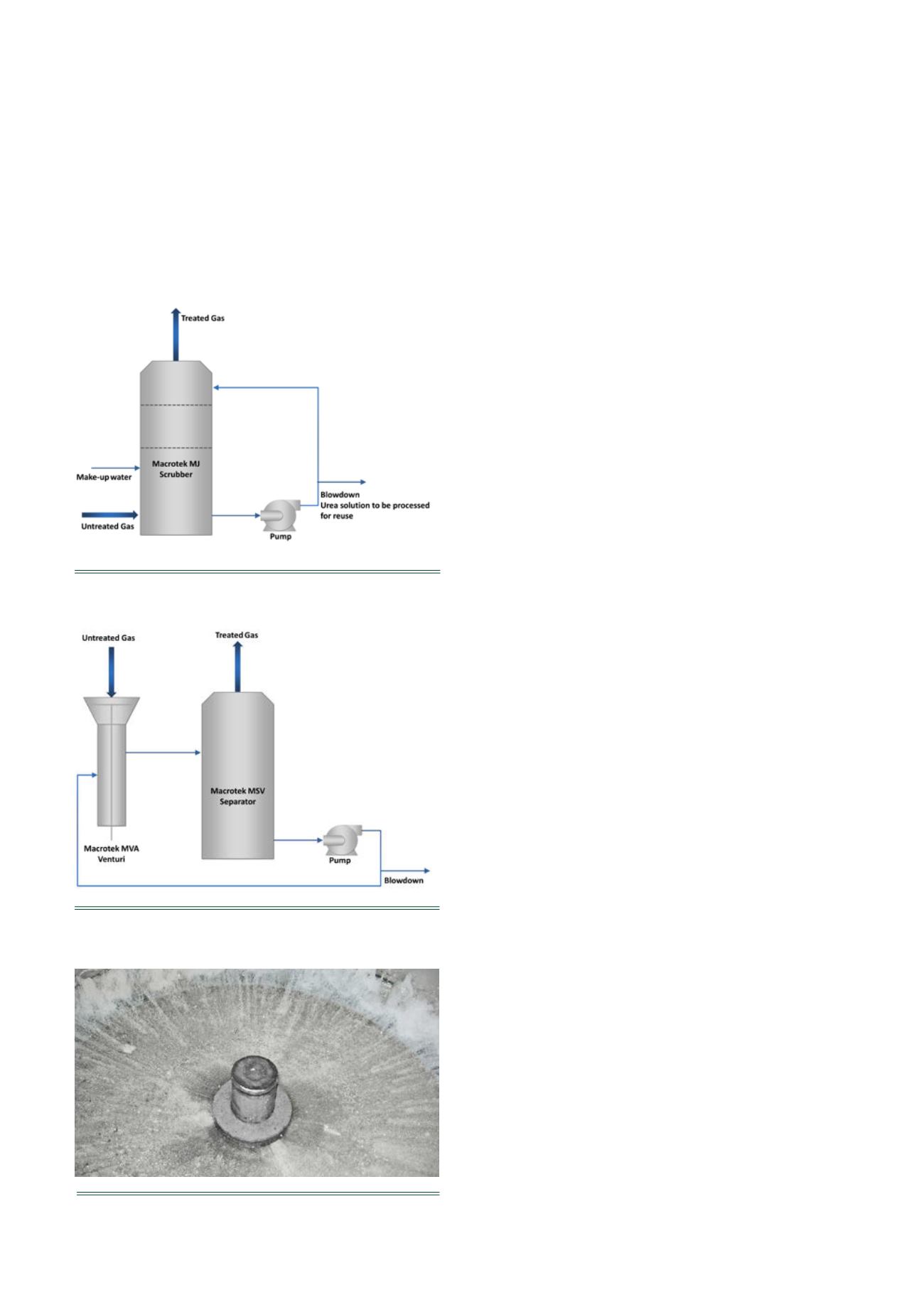

Figure 5.

Process flow diagram of Macrotek MVA venturi

scrubber.

Figure 6.

Flooded disc detail.