NOVEMBER 2016

| WORLD FERTILIZER |

119

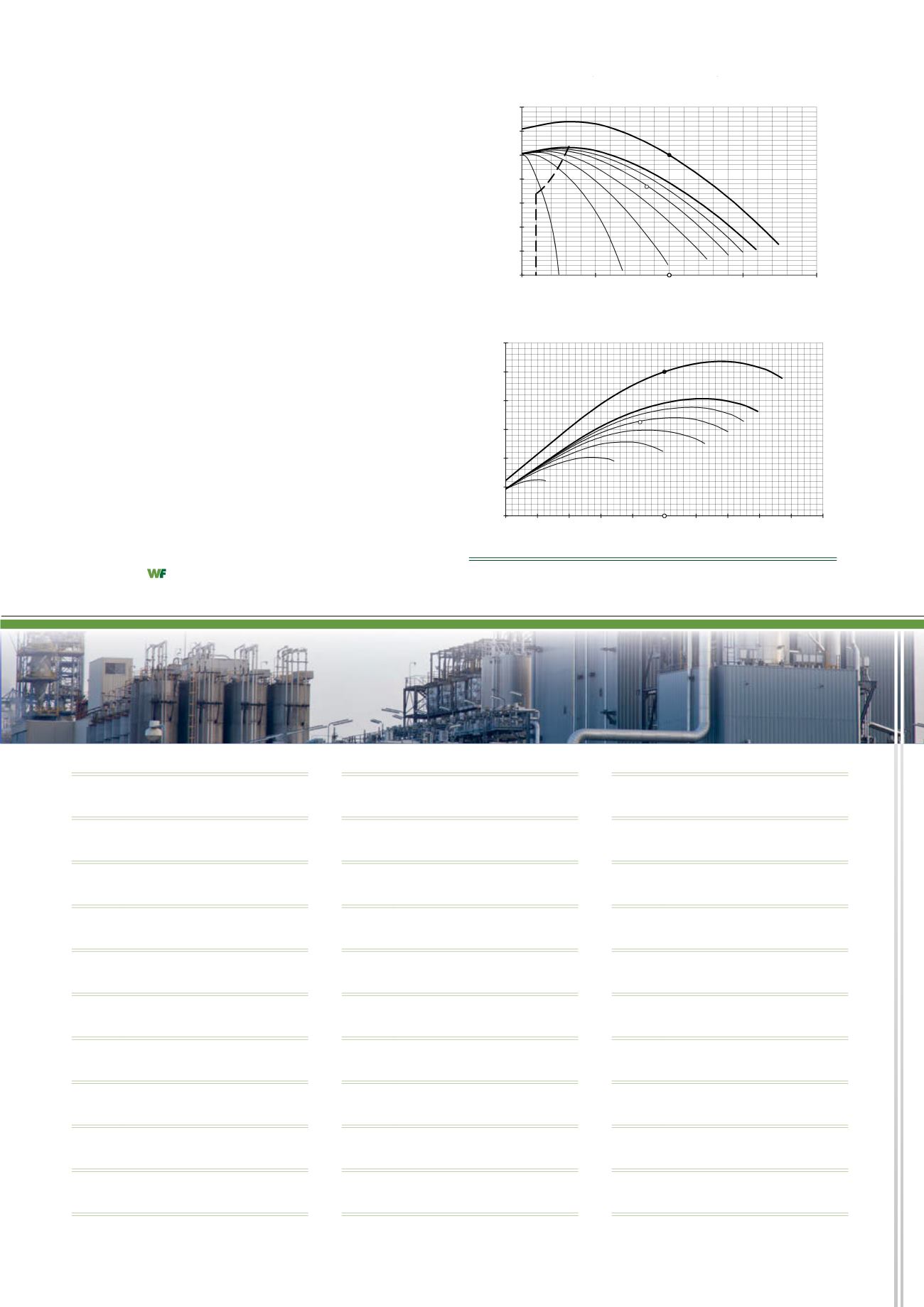

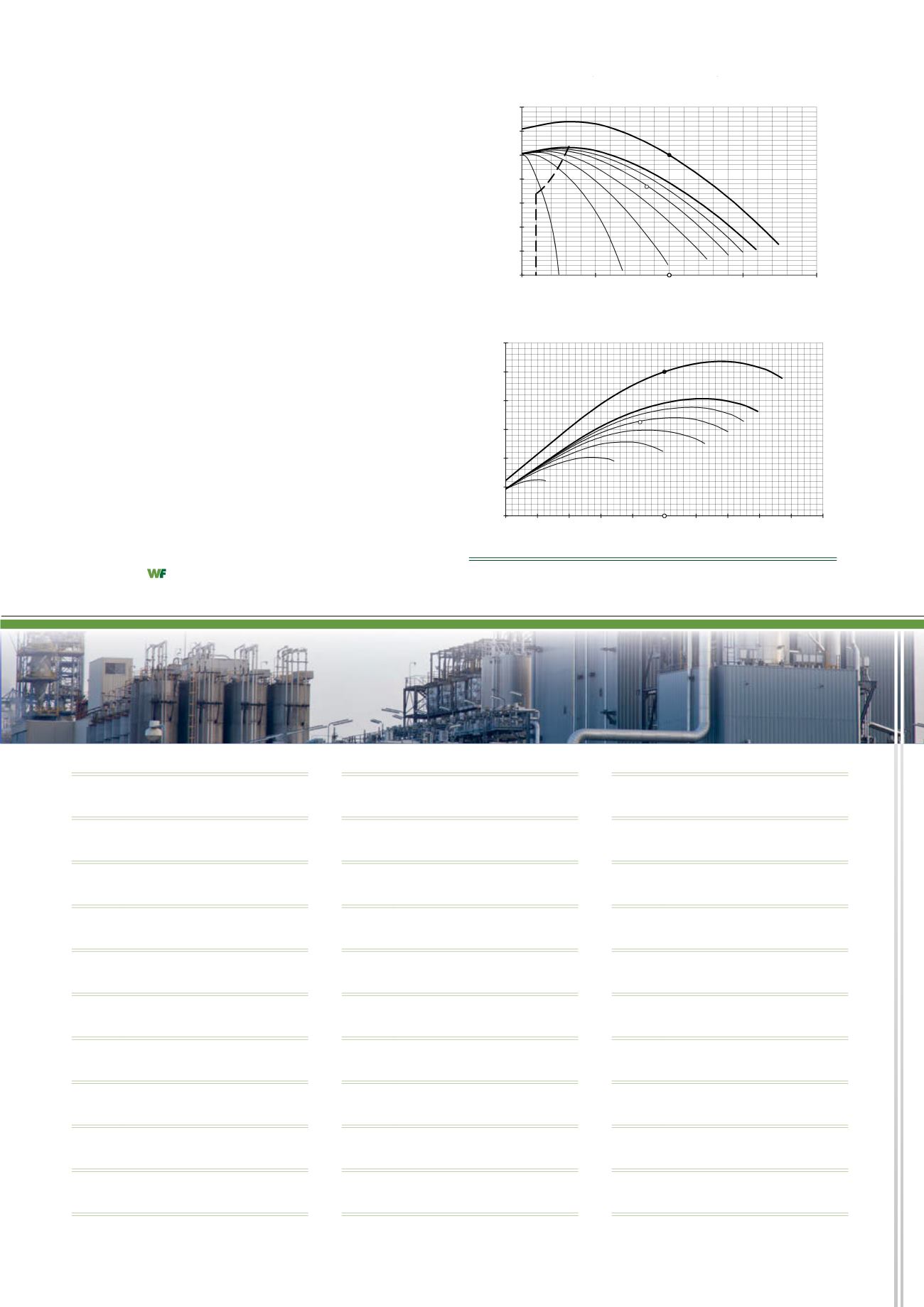

74% with full damper control. Decay of the system

parameters will reduce during switchover from 79% to 85%

in flow rate and from 62% to 72% in pressure, as shown in

Figure 5 for high turbine speed set and low speed turbine set,

respectively.

Conclusion

For a fast switchover, acceleration time and delays in fault

detection time are critical aspects: both will be minimised to

reduce overall switchover time and machine capability to

restore process parameters in due time.

As stated, the acceleration time is dependent on fan inertia

and motor torque capability; fault detection is based on process

monitoring and the time response of the DCS/electrical system.

The operating logic can be tuned to the most appropriate

operating point, ensuring safe and reliable operation during

emergencies. This can be achieved by setting the normal

operating speed of the turbine and fan regulating damper

opening.

Required minimum switchover time is given by process to

avoid reformer trip and it is generally in the range 5 – 20 sec.,

depending on plant size. The overall switchover time is essential

to determine a reliable design to select a proper fan, motor and

turbine.

With experience dating from the 1980s, Boldrocchi has

developed considerable proficiency regarding plant

reliability.

91%

-15°

-30°

-45°

-60°

-75°

-85°

Rated

Normal

100%

0%

20%

40%

60%

80%

100%

120%

140%

0%

50%

100%

150%

200%

Pressure [%]

Flow Rate [%]

FLOW RATE - TOTAL PRESSURE

91%

0°

-15°

-30°

-45°

-60°

-75°

-85°

Rated

Normal

100%

0%

20%

40%

60%

80%

100%

120%

0% 20% 40% 60% 80% 100% 120% 140% 160% 180% 200%

Power [%]

Flow Rate [%]

FLOW RATE - SHAFT POWER

Non operability

area

Figure 6.

Fan performance curves.

58 |

Arvos Group GmbH |

SCHMIDTSCHE SCHACK

IBC |

Atlas Copco

105 |

AUMUND Foerdertechnik

GmbH

45 |

Blasch Precision Ceramics

61 |

BORSIG Process Heat

Exchanger GmbH

64, 74 |

CRU Group

OFC,

97 |

Devco

68 |

DSH Systems

11 |

EcoPhos

85 |

ECS Catalyst

113 |

EMT Blending, Bagging &

Transport Equipment

13 |

Enersul

47 |

Everest Sciences

7 |

Haldor Topsoe

IFC |

John Zink Hamworthy

Combustion

25 |

Johnson Matthey Process

Technologies

82 |

Kimre

73 |

Linde AG

41 |

Ludman Industries

8, 9 |

Matrix Service Co.

91 |

MHI Compressor

International

51 |

Neelam Aqua & Speciality

Chem Ltd

63 |

OHL Gutermuth Industrial

Valves GmbH

OBC |

Pittsburg Corning

53 |

Quest Integrity

81 |

Rembe GmbH

2 |

Sandvik Process Systems

69 |

Solex Thermal Sciences

4 |

thyssenkrupp

17 |

Yokogawa

AD INDEX