104

| WORLD FERTILIZER |

NOVEMBER 2016

n

n

Solutions and techniques available to deal with problems.

n

n

Potential benefits to the end-user.

The Nectar Group manages several bulk ports in

Africa and the Far East and operates a range of handling

equipment in ports across the world, with a specific

focus on handling dry bulk products, such as fertilizers.

The group has handled millions of tonnes of bulk

fertilizers in developing countries over the last 45 years.

Characteristics of fertilizer handling

The most commonly handled fertilizers shipped in bulk

to markets around the world include urea, DAP, NPK,

MOP and MAP. Typically they all show hydroscopic

tendencies that can create ‘damp’ product; however it is

possible for the suppliers to add anti-caking agents to

reduce the effect that moisture has on the material.

Some fertilizers are more prone to ‘lumping’ than others,

such as DAP, which will require additional handling

techniques. The humidity of the tropics mixed with

fluctuating day and night time temperatures can be a

great recipe to create, quite literally, rock solid fertilizers.

From a terminal operator’s point of view, the timely

discharge of the vessels without incurring demurrage

costs or cargo degradation and shrinkage during the

discharge is an important consideration. However the

discharge operation of such cargoes is just one element

of the logistics cycle that stretches from the supplier to

the shipper to the receiver/end-user. The problems that a

terminal operator experiences at the point of discharge

could potentially emanate from shortcomings throughout

the treatment of fertilizers along the logistics chain

before reaching the port of discharge. These oversights

can lead to the deterioration of cargo quality and/or

cargo losses, which presents a variety of problems for all

the parties involved in the logistics chain and, not least,

for the receiver who expects to receive the goods in a

certain condition.

Shipping logistics

For a terminal operator handling fertilizers in a

developing country where remedial resources and

handling equipment can be limited or not available,

discharge operations can prove to be very costly.

There are three key stages in the logistics cycle of

handling fertilizers from shipper to end-user, where

careful consideration is the key to maintaining integrity

of the cargo throughout. These are: the preparation and

shipping of the cargo; the handling of the cargo at the

discharge port; and the direct or indirect delivery to the

end-user from the port.

At the first stage, the shipper has a responsibility to

ensure that the physical characteristics of the cargo

offered at the loading facility from the plant is exactly

what is contracted. Any processes that assist the fertilizer

to maintain its free-flowing properties, such as prilling of

urea cargoes, need to be carried out carefully before

shipping. The quality of the process, as well as proper

inspection and validation of the process before approval

of the cargo for loading, are important steps to maintain

quality.

The hydroscopic property of many types of fertilizers

is inherent in nature and, in order to minimise the

detrimental effect of such properties, cargo temperature

and atmospheric conditions at the load port need to be

carefully monitored during the loading process and

before closing the vessel’s hatches so no problematic

conditions are created upon arrival at the discharge port.

When the fertilizer continues to draw in moisture as it

cools down and loses its free-flowing properties, it

becomes very difficult to handle. Care should be taken to

interrupt loading operation when critical tolerance levels

are reached to minimise costly remedial action further

down the chain.

It is equally important for shippers to provide the

master of the ship with a detailed cargo datasheet as

well as specific instructions as to the care of the cargo

during the sea voyage. The specific instructions related to

the ventilation and temperature control during the sea

voyage and taking into consideration the different

climate conditions between the load and discharge ports

is crucial. The ship should not only carry out such

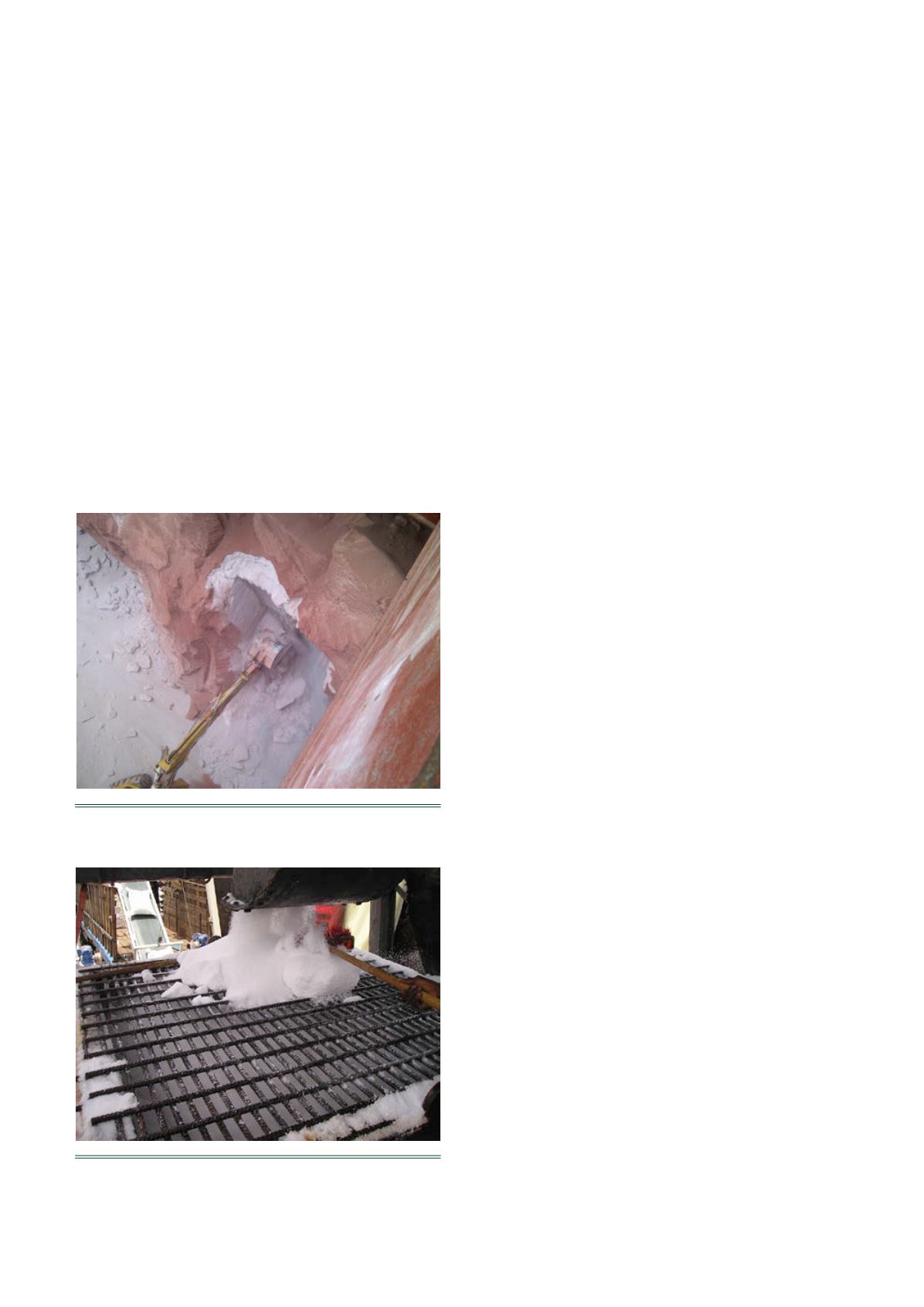

Figure 2.

Handling of moist or lumpy cargo affects the

entire chain.

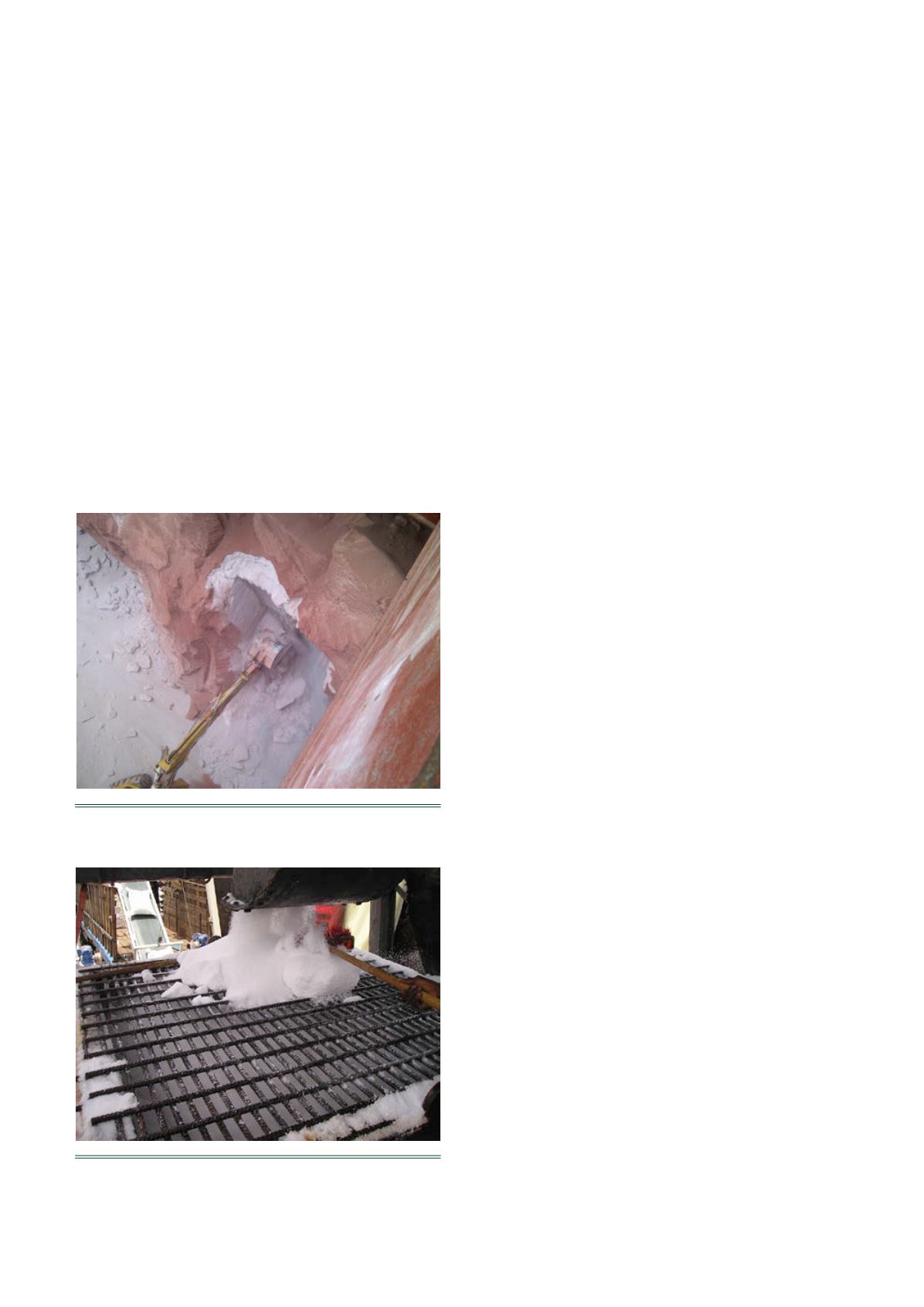

Figure 1.

Discharging hardened fertilizer from a vessel’s

hold is challenging and costly.